MPU6050 Arduino I2C Tutorial: Complete Interfacing, Calibration and Code Examples

The MPU6050 is one of the most powerful and affordable 6-axis motion sensors used in Arduino and IoT projects. It combines a 3-axis accelerometer and a 3-axis gyroscope, which makes it perfect for motion tracking, gesture control, and robotics.

In this tutorial, you will learn how to interface the MPU6050 with Arduino using I2C. We will go step-by-step through the pinout, wiring, registers, and I2C communication. You will also learn how to read raw sensor values, convert them into real units, and calibrate all 3 axes for better accuracy.

We will also compare the MPU6050 with the ADXL345 accelerometer, which we covered earlier in our previous tutorial. This comparison will help you choose the right sensor for your project.

- What is MPU6050 Sensor?

- MPU6050 Pinout and Features

- MPU6050 vs ADXL345: Which One Should You Use?

- Interfacing MPU6050 with Arduino via I2C

- Reading Raw Accelerometer and Gyroscope Values

- Convert Raw Values to ‘g’ and °/s

- MPU6050 Calibration for All 3 Axes

- Final Combined Code : Raw + Converted + Calibrated Values

- Applications of MPU6050 in Arduino Projects

- Conclusion

What is MPU6050 Sensor?

The MPU6050 is a popular motion-tracking sensor used in many Arduino and robotics projects. It comes with a 3-axis accelerometer and a 3-axis gyroscope, both packed inside one small chip. This makes it a complete 6-axis IMU sensor. It can measure tilt, motion, rotation, and orientation in real time. Because it works on the I2C interface, it is easy to connect and simple to use with Arduino.

Overview of the 6-Axis Motion Sensor

The MPU6050 combines two sensors:

- 3-axis accelerometer

Measures linear acceleration along X, Y, and Z axes.

Helps detect tilt, vibration, and movement. - 3-axis gyroscope

Measures rotation rate around X, Y, and Z axes.

Helps track angular motion and orientation.

Together, these six measurements allow you to track the exact movement of any object. This is why the MPU6050 is often used in drones, self-balancing robots, gaming controllers, and IoT devices.

Why MPU6050 is Popular in Arduino Projects

The MPU6050 is very common in Arduino projects because:

- It offers 6-axis motion tracking in a single compact module.

- It uses the simple I2C protocol, so only two wires are needed.

- It provides stable readings with a built-in Digital Motion Processor (DMP).

- It is cheap, easily available, and works on both 3.3V and 5V boards.

- It has a wide measurement range for both accelerometer and gyroscope.

Thanks to these advantages, makers use the MPU6050 in projects like self-balancing robots, gesture control, quadcopters, and wearable devices.

Difference Between Accelerometer and Gyroscope

To understand the MPU6050, you must know how its two main sensors work:

- Accelerometer

Measures acceleration in three directions: X, Y, and Z.

It tells you how fast the sensor is moving in a straight line.

It can also measure the tilt angle because gravity affects its readings. - Gyroscope

Measures angular velocity around three axes.

It tells you how fast the sensor is rotating or turning.

It cannot detect tilt, but it tracks rotational motion very accurately.

In simple words:

Accelerometer = linear movement + tilt

Gyroscope = rotation + angular speed

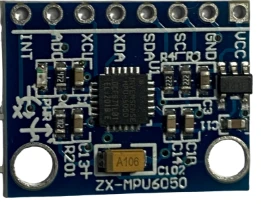

MPU6050 Pinout and Features

Before we connect the MPU6050 to Arduino, it is important to understand its pinout and main features. The module comes with only a few pins, which makes wiring simple and quick. It operates on the I2C communication protocol and works smoothly with most Arduino boards.

MPU6050 Pinout Table

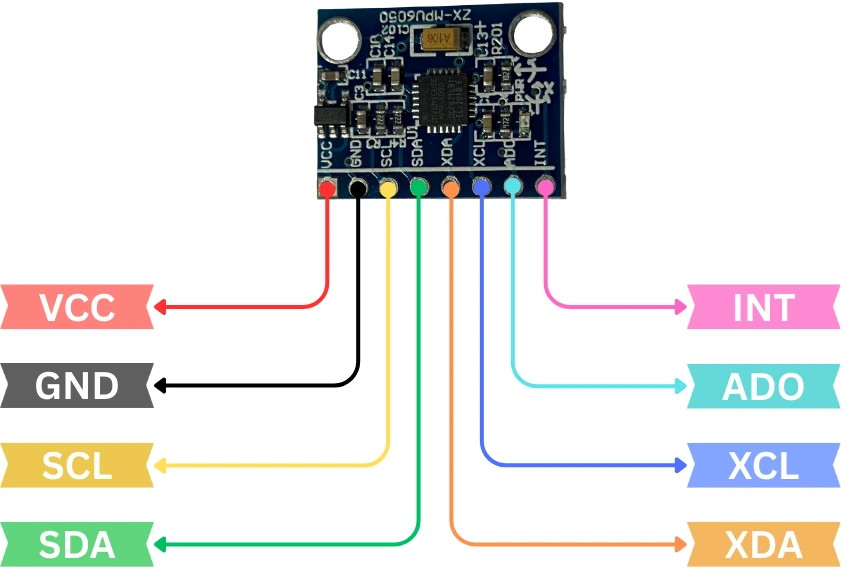

The image below shows the pinout of MPU6050.

The pins and their functions are explained in the table below:

| Pin Name | Function | Description |

|---|---|---|

| VCC | Power Input | Provides power to the module. Supports 3.3V–5V on most breakout boards. |

| GND | Ground | Connects to Arduino ground. |

| SCL | I2C Clock | Serial Clock Line for I2C. Connect to A5 on Uno/Nano. |

| SDA | I2C Data | Serial Data Line for I2C. Connect to A4 on Uno/Nano. |

| INT | Interrupt | Used for motion interrupts or DMP features. Optional. |

| XDA | Aux Data | Auxiliary I2C data line for connecting extra I2C devices. Rarely used. |

| XCL | Aux Clock | Auxiliary I2C clock line. Rarely used. |

| ADO | Address Select | Changes I2C address from 0x68 (default) to 0x69 when pulled high. |

Electrical Characteristics

These basic electrical specs help you understand how the sensor behaves:

- Operating Voltage: 2.3V to 3.4V core (breakout boards allow 3.3V–5V input)

- Communication: I2C up to 400kHz

- Accelerometer Range: ±2g, ±4g, ±8g, ±16g

- Gyroscope Range: ±250, ±500, ±1000, ±2000 °/s

- Current Consumption: ~3.6mA

- I2C Address: 0x68 (default), 0x69 (when ADO pulled high)

These ranges can be selected in the code, depending on your accuracy and speed requirements.

Key Features of MPU6050 Sensor

Some powerful features make the MPU6050 stand out:

- 6-axis IMU (3-axis accelerometer + 3-axis gyroscope)

- Built-in Digital Motion Processor (DMP) for sensor fusion

- Low cost and high availability

- High sensitivity and wide measurement ranges

- Low power consumption

- Stable and smooth real-time motion readings

- Supports fast I2C communication

- Small size, perfect for compact IoT and robotics projects

MPU6050 vs ADXL345: Which One Should You Use?

Before selecting a motion sensor for your Arduino project, it is important to understand the difference between the MPU6050 and the ADXL345. Both sensors measure acceleration, but the MPU6050 also includes a 3-axis gyroscope, making it more powerful for projects that need rotation or orientation tracking.

If you haven’t seen our previous tutorial on ADXL345, you can check it here:

ADXL345 Arduino I2C Tutorial: https://controllerstech.com/adxl345-arduino-i2c-tutorial/

Advantages of MPU6050 Over ADXL345

The MPU6050 offers several strong advantages:

- 6-axis sensing

It combines a 3-axis accelerometer and a 3-axis gyroscope in one chip, making it a complete IMU. - Better motion tracking

Perfect for applications like self-balancing robots, drones, and gesture control. - Built-in DMP (Digital Motion Processor)

Helps reduce noise and performs sensor fusion for smoother results. - Wide measurement ranges

Both accelerometer and gyroscope ranges are flexible and ideal for fast or complex movement. - More stable orientation data

Because gyroscope data helps reduce the noise of accelerometer readings.

In short, MPU6050 is a better choice for motion tracking, orientation, and dynamic movement projects.

When ADXL345 is Still Useful

Even though MPU6050 is powerful, the ADXL345 is still a good choice for many situations:

- When you need only acceleration data

ADXL345 does not have a gyroscope, but for basic tilt or vibration detection, it works well. - Lower power consumption

Useful for battery-operated IoT projects. - When cost matters

ADXL345 modules are slightly cheaper and easier to find. - For simple, static applications

Such as shock detection, tilt sensing, or step counting.

If your project does not need rotation or angular speed, ADXL345 is still a solid option.

Summary of Differences

Here is a quick comparison between both sensors:

| Feature | MPU6050 | ADXL345 |

|---|---|---|

| Sensor Type | 6-axis IMU | 3-axis accelerometer |

| Gyroscope | Yes | No |

| Accelerometer | Yes | Yes |

| Motion Tracking | Excellent | Basic |

| Power Consumption | Medium | Low |

| Best Use | Robots, drones, gesture control, IMU systems | Tilt sensing, vibration, simple motion detection |

| Interface | I2C | I2C/SPI |

| Complexity | Moderate | Easy |

In simple words:

- Choose MPU6050 for advanced motion and rotation tracking.

- Choose ADXL345 for basic acceleration sensing with lower power needs.

Interfacing MPU6050 with Arduino via I2C

The MPU6050 uses the I2C communication protocol, which makes the connection very simple. You only need two data lines to connect it with any Arduino board. In this section, we will look at the components needed, the wiring diagram, and how the I2C address works. Once connected, you can start reading raw accelerometer and gyroscope data easily.

Required Components

You will need the following items:

- Arduino Uno / Nano / Mega

- MPU6050 Module

- Jumper Wires

- Breadboard (optional)

- USB Cable to power the Arduino

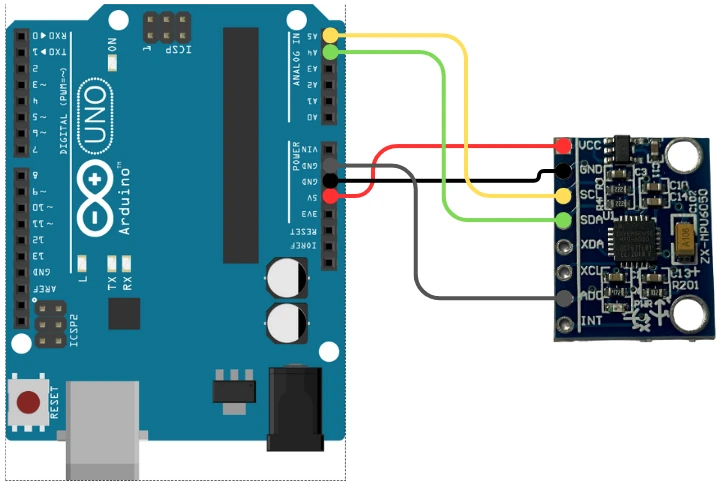

Wiring Diagram of MPU6050 with Arduino

The wiring is very simple because MPU6050 works on I2C. The image below shows the wiring connection between MPU6050 and Arduino.

Here is the connection table:

| MPU6050 Pin | Arduino Uno / Nano Pin | Description |

|---|---|---|

| VCC | 5V or 3.3V | Power supply |

| GND | GND | Ground |

| SCL | A5 | I2C Clock |

| SDA | A4 | I2C Data |

| INT | (Optional) | Interrupt pin |

| ADO | GND | Sets I2C address to 0x68 |

For Arduino Mega, connect SDA → 20 and SCL → 21.

For Arduino Leonardo, connect to the dedicated SDA/SCL pins.

I2C Address and How It Works

The MPU6050 communicates over the I2C bus using a 7-bit address.

It has two possible addresses:

- 0x68 → Default address (ADO pin LOW)

- 0x69 → Alternate address (ADO pin HIGH)

Most breakout boards keep ADO connected to GND, so the default address is 0x68. This is the address your Arduino will use to read and write data from the sensor.

If you ever need two MPU6050 sensors on the same I2C bus, simply pull the ADO pin HIGH on one module to change the address to 0x69.

Reading Raw Accelerometer and Gyroscope Values

Once your MPU6050 is connected to the Arduino, the next step is to read the raw sensor data. These raw values come directly from the sensor registers before any conversion or calibration. Understanding these values is important because you will later convert them into g-force and degrees per second. In this section, we will learn about the required registers and read raw data for both accelerometer and gyroscope.

MPU6050 Register Overview

The MPU6050 stores all accelerometer and gyroscope readings in specific registers. Each axis uses two registers (high byte + low byte). Here are the important ones:

| Sensor | Register Address | Description |

|---|---|---|

| Accelerometer X | 0x3B & 0x3C | High and Low bytes |

| Accelerometer Y | 0x3D & 0x3E | High and Low bytes |

| Accelerometer Z | 0x3F & 0x40 | High and Low bytes |

| Temperature | 0x41 & 0x42 | Raw temperature |

| Gyroscope X | 0x43 & 0x44 | High and Low bytes |

| Gyroscope Y | 0x45 & 0x46 | High and Low bytes |

| Gyroscope Z | 0x47 & 0x48 | High and Low bytes |

Before reading these registers, you must wake up the MPU6050 because it starts in sleep mode. To do that, write 0 to register 0x6B (PWR_MGMT_1).

Read Raw Accelerometer Values

Below is the code to read the RAW acceleration values from the MPU6050.

#include <Wire.h>

#define MPU_ADDR 0x68 // Default I2C address of MPU6050

int16_t AccX, AccY, AccZ;

void setup() {

Wire.begin(); // Start I2C communication

Serial.begin(9600); // Start Serial Monitor

// ----- MPU6050 Initialization -----

Wire.beginTransmission(MPU_ADDR);

Wire.write(0x6B); // PWR_MGMT_1 register

Wire.write(0x00); // Wake up MPU6050 (set sleep = 0)

Wire.endTransmission(true);

// Set accelerometer range to ±2g (most stable)

Wire.beginTransmission(MPU_ADDR);

Wire.write(0x1C); // ACCEL_CONFIG register

Wire.write(0x00); // ±2g range

Wire.endTransmission(true);

// Set sample rate (optional)

Wire.beginTransmission(MPU_ADDR);

Wire.write(0x19); // SMPLRT_DIV register

Wire.write(0x07); // Sample rate = 1kHz / (7+1) = 125Hz

Wire.endTransmission(true);

Serial.println("MPU6050 Initialized for Raw Accelerometer Readings");

}

void loop() {

// Request accelerometer registers starting from 0x3B

Wire.beginTransmission(MPU_ADDR);

Wire.write(0x3B);

Wire.endTransmission(false);

Wire.requestFrom(MPU_ADDR, 6, true);

// Read raw data (16-bit signed)

AccX = (Wire.read() << 8) | Wire.read();

AccY = (Wire.read() << 8) | Wire.read();

AccZ = (Wire.read() << 8) | Wire.read();

Serial.print("AccX: "); Serial.print(AccX);

Serial.print(" | AccY: "); Serial.print(AccY);

Serial.print(" | AccZ: "); Serial.println(AccZ);

delay(200);

}Code Explained (Accelerometer Section)

1. Initialization

- Wake up the sensor from sleep mode

- Set accelerometer range to ±2g for highest accuracy

- Set sample rate to 125Hz

This ensures stable and clean raw readings.

2. Reading Data

- Start reading from register 0x3B

- Read 6 bytes for X, Y, Z

- Combine high and low bytes into a 16-bit signed integer

3. Print Raw Values

Telemeter raw values directly to Serial Monitor.

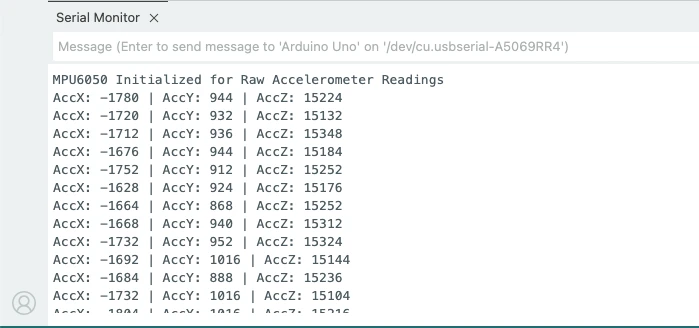

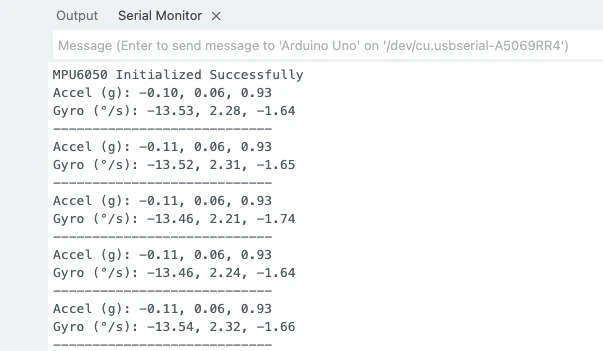

Output on the serial monitor

The image below shows the output of the code. The Raw values are displayed on the serial monitor.

Read Raw Gyroscope Values

Below is the code to read the RAW gyroscope values from the MPU6050.

#include <Wire.h>

#define MPU_ADDR 0x68

int16_t GyroX, GyroY, GyroZ;

void setup() {

Wire.begin();

Serial.begin(9600);

// ----- MPU6050 Initialization -----

Wire.beginTransmission(MPU_ADDR);

Wire.write(0x6B); // Wake up sensor

Wire.write(0x00);

Wire.endTransmission(true);

// Configure gyroscope range to ±250 °/s

Wire.beginTransmission(MPU_ADDR);

Wire.write(0x1B); // GYRO_CONFIG register

Wire.write(0x00); // ±250dps

Wire.endTransmission(true);

Serial.println("MPU6050 Initialized for Raw Gyroscope Readings");

}

void loop() {

// Request gyroscope registers starting from 0x43

Wire.beginTransmission(MPU_ADDR);

Wire.write(0x43);

Wire.endTransmission(false);

Wire.requestFrom(MPU_ADDR, 6, true);

GyroX = (Wire.read() << 8) | Wire.read();

GyroY = (Wire.read() << 8) | Wire.read();

GyroZ = (Wire.read() << 8) | Wire.read();

Serial.print("GyroX: "); Serial.print(GyroX);

Serial.print(" | GyroY: "); Serial.print(GyroY);

Serial.print(" | GyroZ: "); Serial.println(GyroZ);

delay(200);

}Explaination

1. Initialization

- Wake up sensor

- Set gyroscope range to ±250°/s

This gives maximum precision for slow movements.

2. Reading Data

- Read registers starting from 0x43

- Fetch 6 bytes → X, Y, Z

- Combine into signed 16-bit values

3. Print Raw Values

Shows the raw rotation speed (not degrees yet).

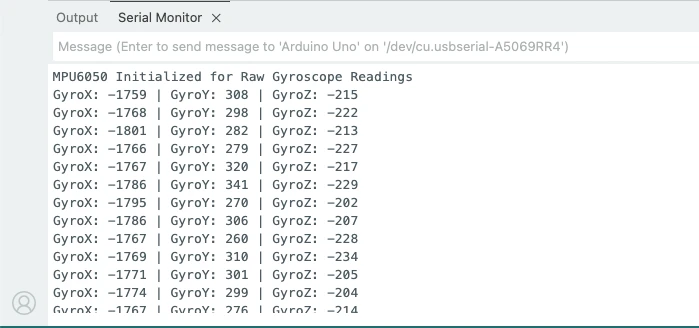

Output on the serial monitor

The image below shows the output of the code. The Raw values are displayed on the serial monitor.

Convert Raw Values to ‘g’ and °/s

When you read data from the MPU6050, the accelerometer and gyroscope values are given as raw 16-bit numbers. These numbers don’t immediately tell you how much acceleration or rotation the sensor is experiencing.

To make the data useful, we convert accelerometer raw values into g-force (g) and gyroscope raw values into degrees per second (°/s). This section explains how these conversions work and provides the full code.

Convert Accelerometer Raw Data to g

The accelerometer measures acceleration along X, Y, Z axes.

The raw values depend on the scale you choose. The most commonly used scale is ±2g, where:

- LSB Sensitivity = 16384 LSB/g

This means:

g_value = raw_value / 16384.0Example:

If raw X = 8192 : X-axis acceleration = 8192 / 16384 = 0.5 g

Convert Gyroscope Raw Data to Degrees per Second

The gyroscope measures rotation around X, Y, Z axes.

With the default full-scale range ±250°/s:

- LSB Sensitivity = 131 LSB/(°/s)

So conversion is:

deg_per_sec = raw_value / 131.0Example:

If raw Z = 262 : Rotation = 262 / 131 = 2 °/s

Complete Code to Print Converted Values

Below is the full Arduino code to read Raw data and convert it to g and °/s.

#include <Wire.h>

#define MPU6050_ADDR 0x68

// MPU6050 Register Addresses

#define SMPLRT_DIV 0x19

#define CONFIG 0x1A

#define GYRO_CONFIG 0x1B

#define ACCEL_CONFIG 0x1C

#define PWR_MGMT_1 0x6B

#define ACCEL_XOUT_H 0x3B

void setup() {

Serial.begin(9600);

Wire.begin();

// Wake up MPU6050

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(PWR_MGMT_1);

Wire.write(0x00); // Clears sleep bit, enables the sensor

Wire.endTransmission();

// Sample Rate Divider

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(SMPLRT_DIV);

Wire.write(0x07); // Sample rate = 1kHz / (7+1) = 125Hz

Wire.endTransmission();

// Digital Low Pass Filter (DLPF)

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(CONFIG);

Wire.write(0x03); // DLPF = 44Hz

Wire.endTransmission();

// Gyroscope configuration

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(GYRO_CONFIG);

Wire.write(0x00); // ±250°/s

Wire.endTransmission();

// Accelerometer configuration

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(ACCEL_CONFIG);

Wire.write(0x00); // ±2g

Wire.endTransmission();

Serial.println("MPU6050 Initialized Successfully");

}

void loop() {

int16_t raw_acc_x, raw_acc_y, raw_acc_z;

int16_t raw_gyro_x, raw_gyro_y, raw_gyro_z;

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(ACCEL_XOUT_H);

Wire.endTransmission(false);

Wire.requestFrom(MPU6050_ADDR, 14, true);

// Reading accelerometer raw values

raw_acc_x = (Wire.read() << 8) | Wire.read();

raw_acc_y = (Wire.read() << 8) | Wire.read();

raw_acc_z = (Wire.read() << 8) | Wire.read();

// Reading temperature (not used)

Wire.read(); Wire.read();

// Reading gyroscope raw values

raw_gyro_x = (Wire.read() << 8) | Wire.read();

raw_gyro_y = (Wire.read() << 8) | Wire.read();

raw_gyro_z = (Wire.read() << 8) | Wire.read();

// Convert raw values to g

float ax = raw_acc_x / 16384.0;

float ay = raw_acc_y / 16384.0;

float az = raw_acc_z / 16384.0;

// Convert raw values to degrees per second

float gx = raw_gyro_x / 131.0;

float gy = raw_gyro_y / 131.0;

float gz = raw_gyro_z / 131.0;

// Print converted values

Serial.print("Accel (g): ");

Serial.print(ax); Serial.print(", ");

Serial.print(ay); Serial.print(", ");

Serial.println(az);

Serial.print("Gyro (°/s): ");

Serial.print(gx); Serial.print(", ");

Serial.print(gy); Serial.print(", ");

Serial.println(gz);

Serial.println("----------------------------");

delay(200);

}Output on the serial monitor

The image below shows the output of the code. The Acceleration values in g and Gyroscope values in °/s are printed on the console.

These values are obtained when the sensor is placed flat on the table. You can see both acceleration and gyroscope values have offset in them. Therefore we now need to calibrate the sensor.

MPU6050 Calibration for All 3 Axes

Calibrating the MPU6050 is an important step before using the sensor for real measurements or motion-based projects. Even small factory offsets can cause inaccurate readings, drift, and unstable results. In this section, we will learn why calibration is required and how to perform it using simple Arduino code.

Why Calibration Is Needed

Every MPU6050 has tiny internal errors that affect the accelerometer and gyroscope. These errors appear even when the sensor is perfectly still.

Typical issues include:

- Accelerometer not showing 0g on X & Y or 1g on Z

- Gyroscope not showing 0°/s on all axes

- Drift when the sensor is used for motion sensing

- Incorrect angle or orientation calculations

Calibration removes these fixed offsets and improves accuracy.

Simple Calibration Method

The easiest calibration method is:

- Place MPU6050 perfectly still on a flat table.

- Read 200–500 samples from the accelerometer and gyroscope.

- Compute the average offset for each axis.

- Subtract this offset from future raw readings.

You only need to do this once unless you remount the sensor.

Code for Accelerometer Calibration

Below is the full Arduino code to calibrate the acceleration values in the MPU6050 sensor.

#include <Wire.h>

#define MPU6050_ADDR 0x68

#define ACCEL_XOUT_H 0x3B

long accX_offset = 0, accY_offset = 0, accZ_offset = 0;

void setup() {

Serial.begin(9600);

Wire.begin();

// Wake up MPU6050

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(0x6B);

Wire.write(0);

Wire.endTransmission();

delay(1000);

calibrateAccelerometer();

}

void loop() {

// Nothing here - calibration prints automatically

}

void calibrateAccelerometer() {

long sumX = 0, sumY = 0, sumZ = 0;

Serial.println("Calibrating Accelerometer... Keep the sensor still.");

for (int i = 0; i < 200; i++) {

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(ACCEL_XOUT_H);

Wire.endTransmission(false);

Wire.requestFrom(MPU6050_ADDR, 6, true);

int16_t rawX = (Wire.read() << 8) | Wire.read();

int16_t rawY = (Wire.read() << 8) | Wire.read();

int16_t rawZ = (Wire.read() << 8) | Wire.read();

sumX += rawX;

sumY += rawY;

sumZ += rawZ;

delay(5);

}

accX_offset = sumX / 200;

accY_offset = sumY / 200;

accZ_offset = (sumZ / 200) - 16384; // 1g correction (Z-axis)

Serial.println("Accelerometer Calibration Done:");

Serial.print("X Offset = "); Serial.println(accX_offset);

Serial.print("Y Offset = "); Serial.println(accY_offset);

Serial.print("Z Offset = "); Serial.println(accZ_offset);

}Explanation

- The MPU6050 is first woken up by writing

0to register0x6B. - The code reads raw accelerometer values 200 times.

- Averages of these raw values become the offset.

- For Z-axis, 16384 is subtracted because this is the 1g value in ±2g mode.

- These offsets are printed for applying in future programs.

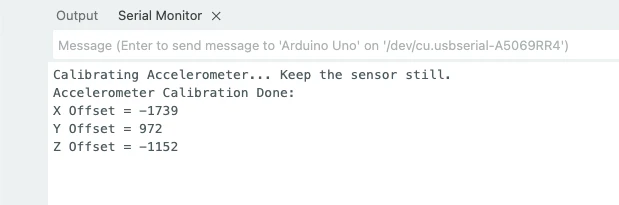

Output on the serial monitor

The image below shows the output of the code. The offsets in X, Y and Z axes are printed on the serial console.

Code for Gyroscope Calibration

Below is the full Arduino code to calibrate the gyroscope values in the MPU6050 sensor.

#include <Wire.h>

#define MPU6050_ADDR 0x68

#define GYRO_XOUT_H 0x43

long gyroX_offset = 0, gyroY_offset = 0, gyroZ_offset = 0;

void setup() {

Serial.begin(9600);

Wire.begin();

// Wake up MPU6050

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(0x6B);

Wire.write(0);

Wire.endTransmission();

delay(1000);

calibrateGyroscope();

}

void loop() {

// Nothing here - calibration prints automatically

}

void calibrateGyroscope() {

long sumX = 0, sumY = 0, sumZ = 0;

Serial.println("Calibrating Gyroscope... Keep the sensor still.");

for (int i = 0; i < 200; i++) {

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(GYRO_XOUT_H);

Wire.endTransmission(false);

Wire.requestFrom(MPU6050_ADDR, 6, true);

int16_t rawX = (Wire.read() << 8) | Wire.read();

int16_t rawY = (Wire.read() << 8) | Wire.read();

int16_t rawZ = (Wire.read() << 8) | Wire.read();

sumX += rawX;

sumY += rawY;

sumZ += rawZ;

delay(5);

}

gyroX_offset = sumX / 200;

gyroY_offset = sumY / 200;

gyroZ_offset = sumZ / 200;

Serial.println("Gyroscope Calibration Done:");

Serial.print("X Offset = "); Serial.println(gyroX_offset);

Serial.print("Y Offset = "); Serial.println(gyroY_offset);

Serial.print("Z Offset = "); Serial.println(gyroZ_offset);

}Explanation

- The code reads raw gyroscope values 200 times.

- The averages of X, Y, and Z form the gyroscope offsets.

- Since the gyro should read 0°/s when stationary, these offsets represent the unwanted drift.

- These values must be subtracted from future gyro data.

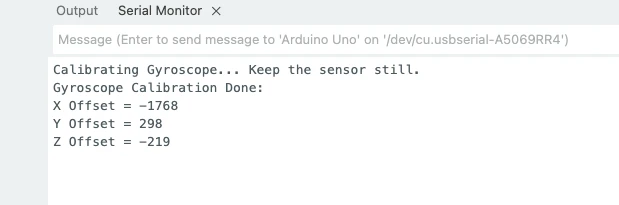

Output on the serial monitor

The image below shows the output of the code. The offsets in X, Y and Z axes are printed on the serial console.

Applying Offsets in Your Main Code

You will use the calibration values like this:

accX = rawAccX - accX_offset;

accY = rawAccY - accY_offset;

accZ = rawAccZ - accZ_offset;

gyroX = rawGyroX - gyroX_offset;

gyroY = rawGyroY - gyroY_offset;

gyroZ = rawGyroZ - gyroZ_offset;Final Combined Code : Raw + Converted + Calibrated Values

In this final section, we will combine everything we have learned: reading raw data, converting the values into g and degrees per second, and applying calibration offsets. This single Arduino sketch gives you clean, stable accelerometer and gyroscope readings. You can use it directly in your projects such as robotics, gesture sensing, motion tracking, and IMU-based applications.

Full Arduino Code

The code below includes:

- MPU6050 initialization

- Calibration for accelerometer and gyroscope

- Reading raw values

- Applying offsets

- Converting data to g and °/s

- Printing everything on the Serial Monitor

#include <Wire.h>

// MPU6050 Registers

#define MPU6050_ADDR 0x68

#define ACCEL_XOUT_H 0x3B

#define GYRO_XOUT_H 0x43

// Calibration Offsets

long accX_offset = 0, accY_offset = 0, accZ_offset = 0;

long gyroX_offset = 0, gyroY_offset = 0, gyroZ_offset = 0;

// Scales

float accScale = 16384.0; // For ±2g

float gyroScale = 131.0; // For ±250 °/s

void setup() {

Serial.begin(9600);

Wire.begin();

// Wake up MPU6050 – write 0 to power management register

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(0x6B);

Wire.write(0);

Wire.endTransmission();

delay(1000);

calibrateAccelerometer();

calibrateGyroscope();

Serial.println("\nStarting Final Reading...\n");

}

void loop() {

int16_t rawAccX, rawAccY, rawAccZ;

int16_t rawGyroX, rawGyroY, rawGyroZ;

// ------ Read Accelerometer ------

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(ACCEL_XOUT_H);

Wire.endTransmission(false);

Wire.requestFrom(MPU6050_ADDR, 6, true);

rawAccX = (Wire.read() << 8) | Wire.read();

rawAccY = (Wire.read() << 8) | Wire.read();

rawAccZ = (Wire.read() << 8) | Wire.read();

// Apply offsets

rawAccX -= accX_offset;

rawAccY -= accY_offset;

rawAccZ -= accZ_offset;

// Convert to g

float ax = rawAccX / accScale;

float ay = rawAccY / accScale;

float az = rawAccZ / accScale;

// ------ Read Gyroscope ------

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(GYRO_XOUT_H);

Wire.endTransmission(false);

Wire.requestFrom(MPU6050_ADDR, 6, true);

rawGyroX = (Wire.read() << 8) | Wire.read();

rawGyroY = (Wire.read() << 8) | Wire.read();

rawGyroZ = (Wire.read() << 8) | Wire.read();

// Apply offsets

rawGyroX -= gyroX_offset;

rawGyroY -= gyroY_offset;

rawGyroZ -= gyroZ_offset;

// Convert to degrees/sec

float gx = rawGyroX / gyroScale;

float gy = rawGyroY / gyroScale;

float gz = rawGyroZ / gyroScale;

// -------- Print Results --------

Serial.print("Acc(g): ");

Serial.print(ax); Serial.print(", ");

Serial.print(ay); Serial.print(", ");

Serial.println(az);

Serial.print("Gyro(dps): ");

Serial.print(gx); Serial.print(", ");

Serial.print(gy); Serial.print(", ");

Serial.println(gz);

Serial.println("---------------------");

delay(200);

}

// ---------------- Calibration Functions ---------------- //

void calibrateAccelerometer() {

long sumX = 0, sumY = 0, sumZ = 0;

Serial.println("Calibrating Accelerometer... Do not move!");

for (int i = 0; i < 200; i++) {

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(ACCEL_XOUT_H);

Wire.endTransmission(false);

Wire.requestFrom(MPU6050_ADDR, 6, true);

sumX += (Wire.read() << 8) | Wire.read();

sumY += (Wire.read() << 8) | Wire.read();

sumZ += (Wire.read() << 8) | Wire.read();

delay(5);

}

accX_offset = sumX / 200;

accY_offset = sumY / 200;

accZ_offset = (sumZ / 200) - 16384; // 1g adjustment

Serial.println("Accelerometer Calibration Done.");

}

void calibrateGyroscope() {

long sumX = 0, sumY = 0, sumZ = 0;

Serial.println("Calibrating Gyroscope... Do not move!");

for (int i = 0; i < 200; i++) {

Wire.beginTransmission(MPU6050_ADDR);

Wire.write(GYRO_XOUT_H);

Wire.endTransmission(false);

Wire.requestFrom(MPU6050_ADDR, 6, true);

sumX += (Wire.read() << 8) | Wire.read();

sumY += (Wire.read() << 8) | Wire.read();

sumZ += (Wire.read() << 8) | Wire.read();

delay(5);

}

gyroX_offset = sumX / 200;

gyroY_offset = sumY / 200;

gyroZ_offset = sumZ / 200;

Serial.println("Gyroscope Calibration Done.");

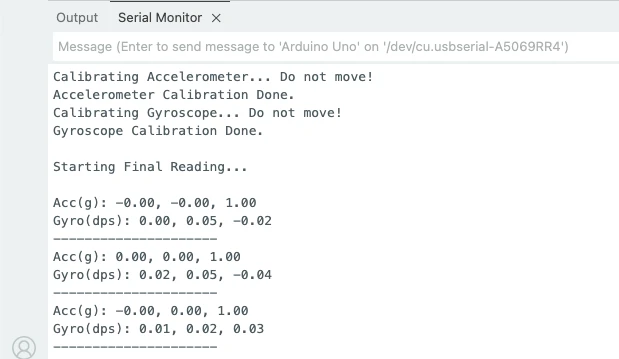

}Output on the serial monitor

The image below shows the output of the code.

You can see in the image, after calibration, the acceleration values are precise. The acceleration in z-axis is 1g, whereas in x-axis and y-axis it is 0.

The gyroscope also shows values near to 0 as the sensor is kept stationary.

Meaning of the values:

- Accelerometer values near 0, 0, 1 indicate proper calibration.

- Gyroscope values near 0°/s show stable results.

- Small variations are normal because of sensor noise.

How to Verify the Working

You can easily check the sensor by:

1. Tilting the board

- If you tilt the sensor forward or sideways, the corresponding axis should move smoothly.

- No sudden jumps or drift.

2. Rotate the board

- Gyroscope values should increase only during movement.

- When still, they should return to zero.

Applications of MPU6050 in Arduino Projects

The MPU6050 is widely used in many Arduino projects because it provides both accelerometer and gyroscope data in a single compact module. Its fast response, low noise, and 6-axis sensing make it perfect for motion-based applications. Here are some of the most common and practical uses of the MPU6050 in Arduino projects.

Self-Balancing Robots

Self-balancing robots, such as two-wheel Segway-style robots, depend heavily on MPU6050.

The sensor provides pitch and roll angles, which help the robot stay upright by constantly correcting its position.

The gyroscope detects quick rotational changes while the accelerometer keeps the overall tilt stable. Together, they allow smooth and responsive balancing.

Gesture Control Systems

MPU6050 is also used in gesture-controlled projects such as:

- Controlling robots with hand movements

- Wireless mouse or cursor control

- Swipe, tilt, or rotation-based controls

The fast accelerometer and gyro readings make it easy to track hand gestures and map them to actions.

IMU Based Motion Tracking

In many DIY IMU (Inertial Measurement Unit) projects, the MPU6050 is the first choice.

It helps track movement and orientation over time.

Common examples include:

- VR head tracking

- Game controllers

- Drone flight stabilization

- Wearable motion trackers

Its combination of 3-axis acceleration + 3-axis rotation gives accurate and real-time movement detection, making it ideal for motion-tracking applications.

Conclusion

The MPU6050 is a highly reliable and beginner-friendly motion sensor that combines a 3-axis accelerometer and 3-axis gyroscope in a single module, making it ideal for Arduino-based robotics and IoT projects. In this tutorial, you learned how the sensor works internally, explored its pinout and features, and compared it with the ADXL345 to understand when each sensor is the better choice. You also saw how to connect the MPU6050 to Arduino over I2C and how to read the raw accelerometer and gyroscope data it provides.

Beyond basic interfacing, the tutorial walked you through converting raw readings into meaningful units like g-force and degrees per second, followed by a full 3-axis calibration procedure to ensure accuracy. You also implemented a final combined sketch that delivers clean, stable, and reliable measurements suitable for real-world applications such as self-balancing robots, gesture-controlled systems, and IMU-based motion tracking. For further learning, you can explore related sensor guides, including the ADXL345 Arduino I2C tutorial on Controllerstech.

Browse More Arduino Sensors Tutorials

Arduino PIR Motion Sensor Tutorial: Wiring, Modes, Sensitivity & Full Codes

Interface DHT11 and DHT22 with Arduino | Temperature and Humidity Sensor Tutorial

Arduino BME280 Tutorial: Wiring, Pinout, Code and LCD1602 Display Output

IR Sensor Arduino Tutorial: Interfacing, Calibration, Detection Modes, Codes & LCD1602 Display

Interface SHT21 Temperature and Humidity Sensor with Arduino | Display on Serial Monitor and I2C LCD

Arduino DS18B20 Temperature Sensor Tutorial: Single and Multiple Sensors with SSD1306 OLED

Interface AHT20 Sensor with Arduino | Measure Temperature and Humidity with OLED Display

Arduino MPU6050 Project Download

Info

You can help with the development by DONATING Below.

To download the project, click the DOWNLOAD button.

Arduino MPU6050 FAQs

The MPU6050 offers better stability because the accelerometer and gyroscope data can be combined using onboard DMP for improved precision.

Yes. For boards like Arduino Due, ESP32, or STM32, you can connect it directly because they already use 3.3V logic.

This usually happens due to noise on the I2C lines or insufficient grounding. Adding pull-up resistors or shortening the wires helps.

Calibration is recommended whenever the module is moved, re-mounted, or used in a new orientation.

Yes. You can adjust the internal digital low-pass filter (DLPF) and sample rate divider registers to achieve higher sampling frequencies.