Last Updated: September 29, 2025

Getting Started with FDCAN Normal Mode on STM32

This tutorial explains how to use STM32 FDCAN in Normal Mode with a focus on message RAM configuration and filter setup. While the previous guide covered loopback mode, here we will set up two FDCAN peripherals on STM32H7 to communicate with each other. Developers often search for stm32 fdcan example, hal_fdcan_addmessagetotxfifoq, or fdcan filter configuration, so we’ll cover those with code examples.

You’ll also learn about HAL_FDCAN_ActivateNotification, HAL_FDCAN_GetRxMessage, and FIFO callbacks. By the end, you’ll be ready to implement reliable FDCAN communication in your STM32 projects.

As you already know we need at least 2 can devices to use the normal mode. I don’t have another FDCAN device, but my STM32H7 board has 2 FDCAN peripherals. So I am going to communicate between those 2 FDCAN peripherals.

This brings us to a very important parameter in the FDCAN configuration, the message RAM. When using more than 1 FDCAN peripheral, we need to assign the message RAM to each peripheral. This is something we will see new in this tutorial, whereas the basic configuration will remain same as FDCAN Loopback Mode.

STM32 FDCAN Normal Mode Video Tutorial

While this written guide covers the complete setup, configuration, and code for FDCAN in Normal Mode, a live demonstration can often make the process much easier to follow. That’s why I’ve also prepared a full video tutorial that walks you through the entire implementation step by step. Use the written instructions alongside the video to strengthen your understanding and catch important details that are easier to see in real-time.

Watch the Video- Introduction to FDCAN in STM32

- Understanding Normal Mode in FDCAN

- The FDCAN Frame Structure

- Hardware Connection for FDCAN Communication (CANH & CANL Wiring)

- Hardware Required for FDCAN Project

- STM32CubeMX Configuration for FDCAN

- FDCAN Filter Configuration

- STM32 FDCAN Code Walkthrough

- Result of the STM32 FDCAN Communication

- Conclusion

Introduction to FDCAN in STM32

What is FDCAN and Why Use It?

FDCAN, or Flexible Data-Rate Controller Area Network, is a communication protocol that lets microcontrollers talk to each other quickly and reliably. Unlike standard CAN, FDCAN supports higher data speeds and flexible message sizes. STM32 microcontrollers use FDCAN to connect with sensors, motors, and other devices in automotive, industrial, and robotics projects. You use FDCAN when you need fast, stable, and error-free communication between multiple devices.

Key Features of FDCAN in STM32 Microcontrollers

STM32 microcontrollers come with a built-in FDCAN controller that makes setup and communication easier. Some key features include:

- Flexible Data Rate: Supports both standard and fast data speeds.

- Error Detection: Built-in error checking keeps your communication reliable.

- Multiple Message Objects: Handles many messages at the same time.

- Low Latency: Quick data transmission with minimal delay.

- Filter Options: Lets you receive only the messages you need.

These features make STM32 FDCAN perfect for real-time communication in complex systems.

Understanding Normal Mode in FDCAN

Difference Between Normal Mode and Other Modes

FDCAN supports several operating modes, each designed for a specific purpose. Normal Mode is the standard mode where the node actively participates in the network: it can send and receive messages, acknowledge frames, and detect errors.

Other modes include:

- Loopback Mode: The node only tests its own transmission without sending data on the bus.

- Silent Mode: The node listens to messages but does not transmit or acknowledge.

- Restricted Mode: Combines features like silent and limited communication for diagnostics.

Unlike these special modes, Normal Mode enables full communication, making it suitable for real-time network operation.

When to Use FDCAN Normal Mode

Use Normal Mode when your STM32 is part of an active CAN or CAN-FD network and needs to:

- Transmit messages to other nodes.

- Receive messages from sensors, controllers, or actuators.

- Detect and report errors on the bus.

Normal Mode is the default operating mode for most real-world applications where continuous communication is required.

The FDCAN Frame Structure

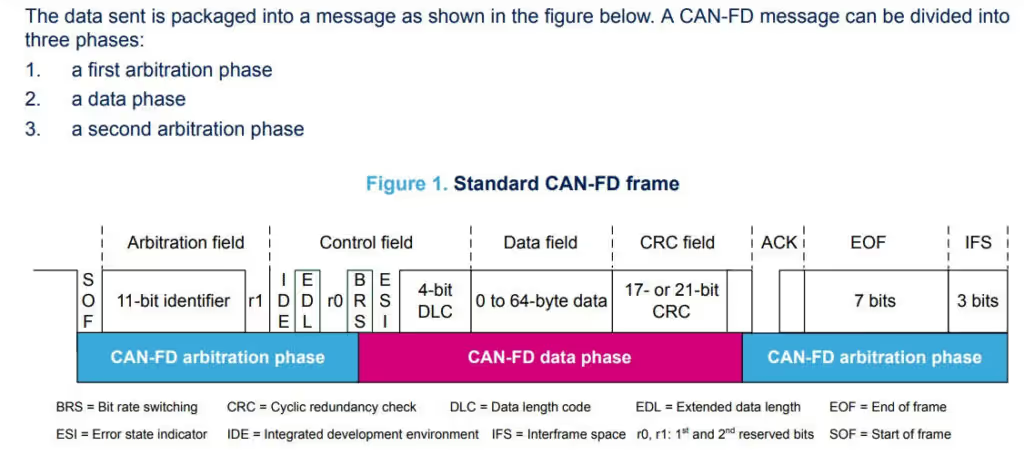

Below is an illustration showing the structure of an FDCAN frame:

Understanding the FDCAN Frame

The FDCAN frame is divided into three main phases:

- First Arbitration Phase

This phase identifies the message and its purpose:- Start of Frame (SOF): Marks the beginning of the message.

- ID and Control Bits: Include the message ID, indicate whether data is being sent or requested, and specify the protocol type (CAN or CAN-FD) and speed configuration.

- Data Transmission Phase

Here the actual information is sent:- Data Length Code (DLC): Shows how many bytes of data are included.

- Data: The actual message content you want to transmit.

- Cyclic Redundancy Check (CRC): Verifies data integrity.

- Dominant Bit: Signals control for proper timing and synchronization.

- Second Arbitration Phase

This phase confirms successful message delivery:- Acknowledgment (ACK): Sent by receivers to confirm the message was received.

- End of Frame (EOF): Marks the end of the message.

During the Interframe Space (IFS), no data is transmitted. This pause separates one frame from the next.

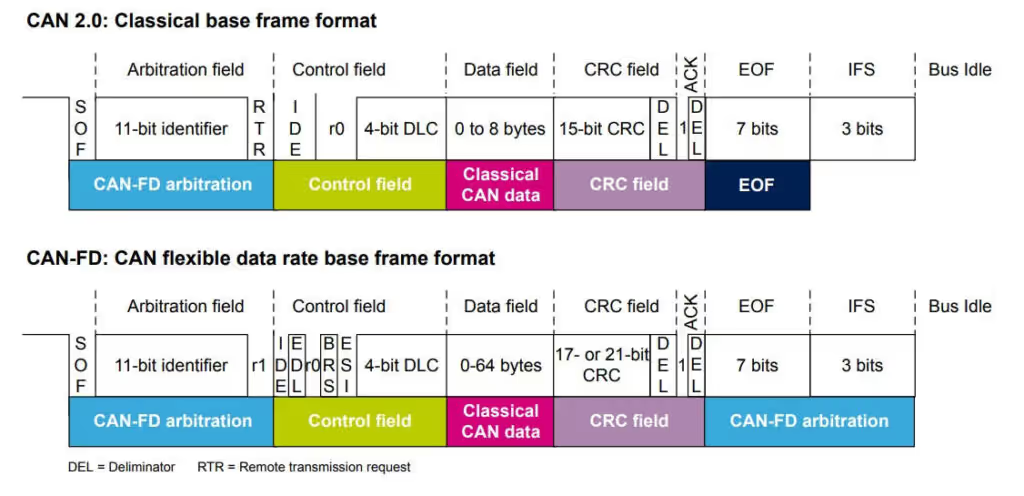

Frame Architecture: CAN 2.0 vs CAN-FD

Let’s compare how CAN 2.0 and CAN-FD frames differ:

- Frame Type:

- CAN 2.0 uses the RTR bit to indicate a data frame (dominant) or a remote frame (recessive).

- CAN-FD always uses a dominant reserved (RRS) bit since it supports only data frames.

- New Control Bits in CAN-FD:

- EDL (Extended Data Length): Recessive to indicate a CAN-FD frame; in CAN 2.0, this bit is called R0.

- BRS (Bit Rate Switching): Indicates if a higher bit rate is used during the data phase.

- ESI (Error State Indicator): Shows whether the node is in an error-active or error-passive state.

Main Differences Between CAN-FD and CAN 2.0

Here’s a visual summary of the key differences:

- CAN-FD supports larger payloads and faster data rates.

- It has additional control bits for flexibility, error detection, and speed switching.

- CAN 2.0 is simpler, supporting only fixed data length and a single bit rate.

Hardware Connection for FDCAN Communication (CANH & CANL Wiring)

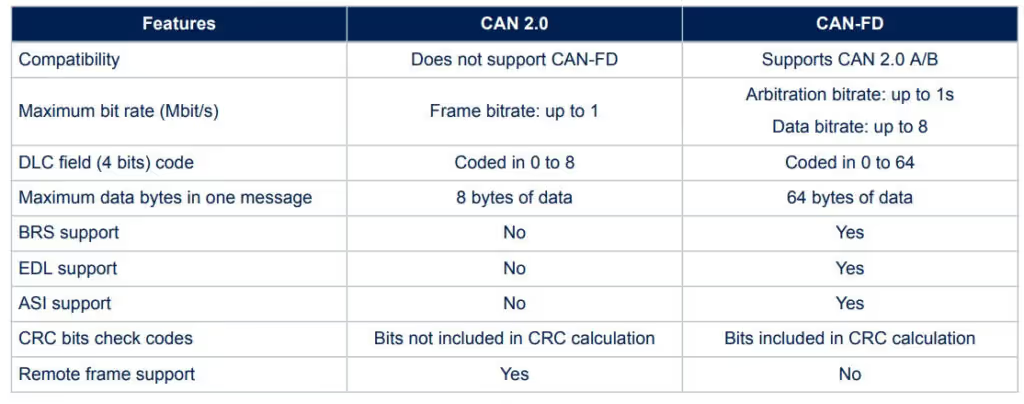

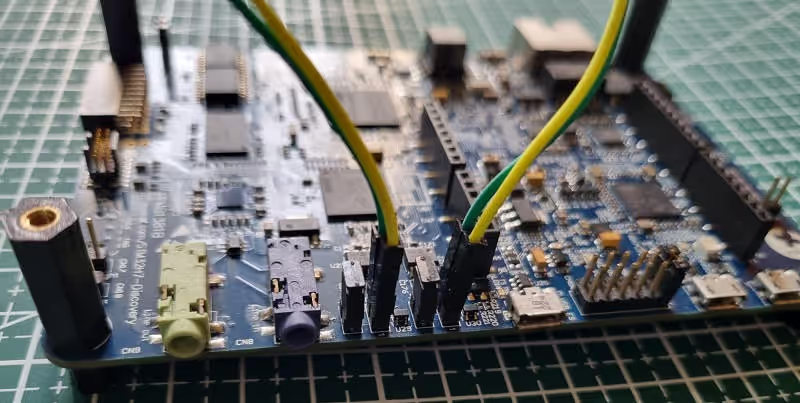

As mentioned earlier, I will use both FDCAN peripherals on the same STM32 board. Since the board already has two built-in transceivers, all we need to do is connect CANH to CANH and CANL to CANL.

Below is an image showing the exact connections:

Hardware Required for FDCAN Project

Here are the components used in this project. Some links are affiliate links that help support this work at no extra cost to you:

STM32CubeMX Configuration for FDCAN

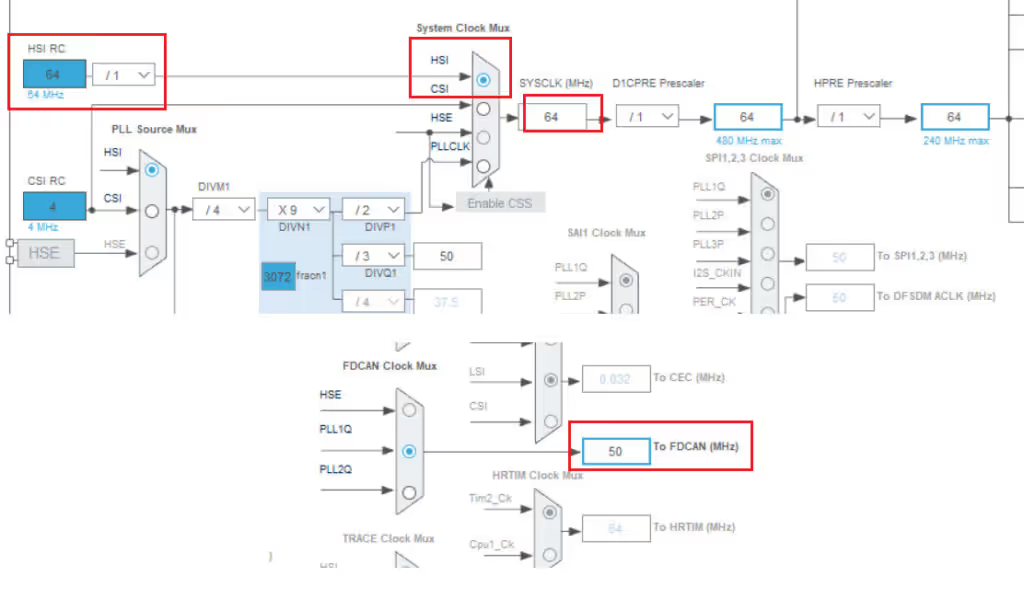

STM32 Clock Configuration

Let’s start by configuring the clock first.

I am choosing the 64 MHz internal clock in this tutorial. The reason for the same will be explained in a while. Also note that the FDCAN clock is 50 MHz. This will be used in the later part of the tutorial.

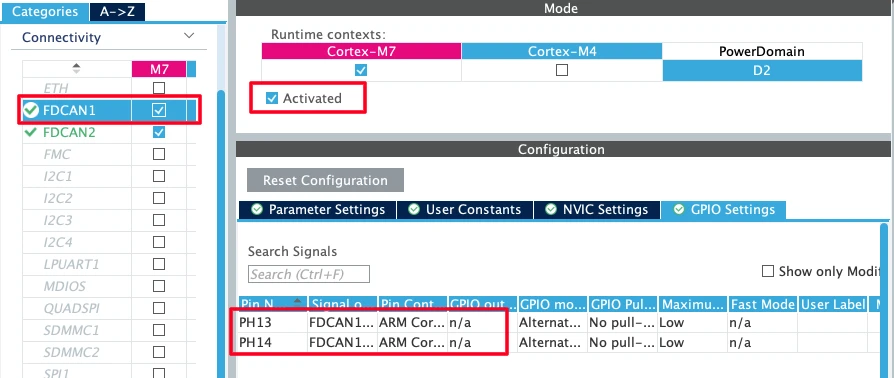

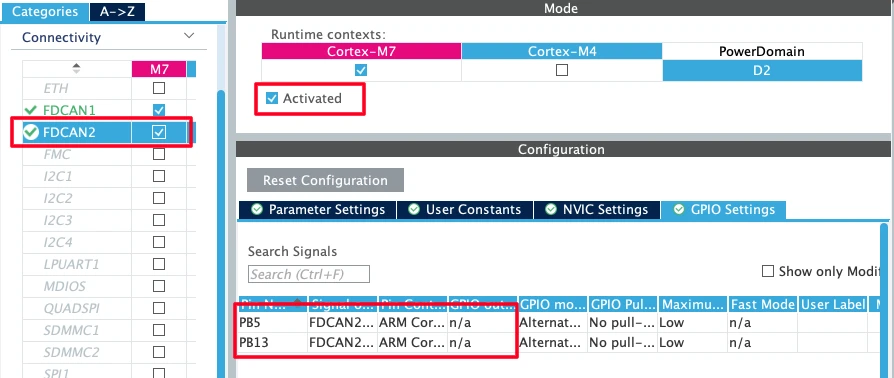

Enable STM32 FDCAN

Now enable the FDCAN peripherals for the cortex M7.

Here I have enabled the FDCAN1 and FDCAN2 for the cortex M7. Note the pins PH13 is the TX pin and PH14 is the RX pin in FDCAN1 and similarly PB5 and PB13 are the pins used for FDCAN2.

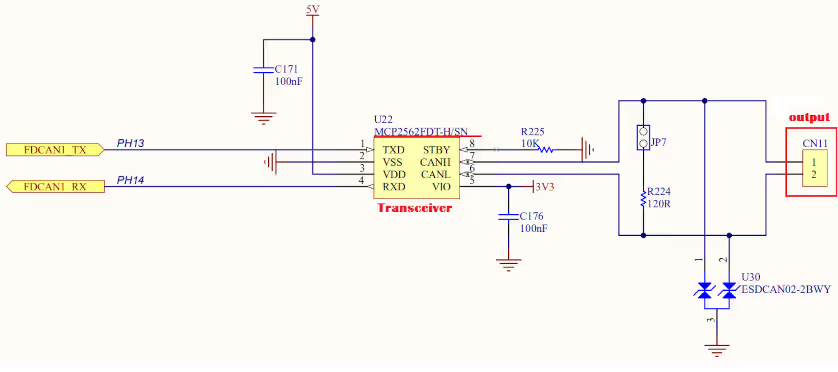

The controller I’m using, STM32H745 Discovery, has a built-in CAN transceiver on the board. The MCP2562FDT transceiver connects to pins PH13 (CANH) and PH14 (CANL). The board provides dedicated connectors for CANH and CANL, as shown in the image below:

STM32 FDCAN common Configuration

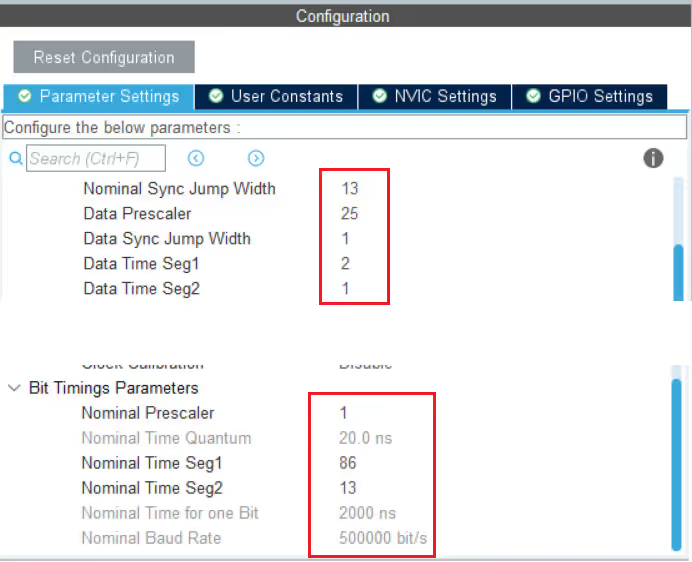

First we will take a look at the common configuration for both FDCAN1 and FDCAN2. This part includes Sync jump width, Prescaler, Time segment etc. In order to achieve the same board rate, both the peripherals must be configured similarly.

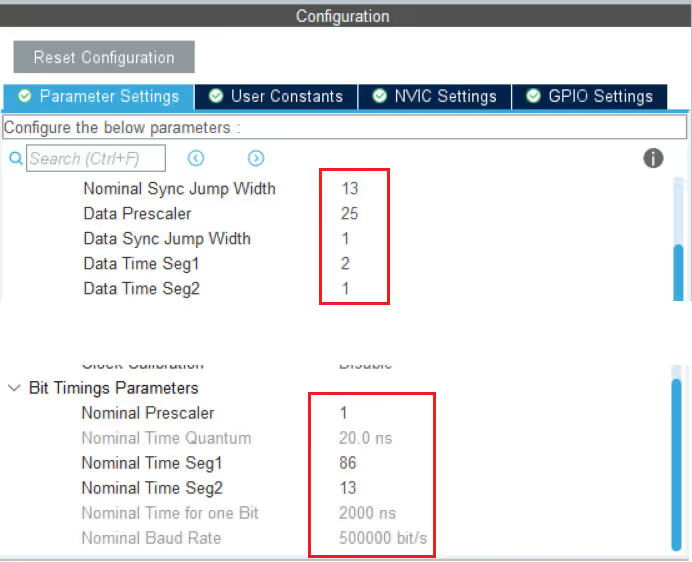

The image below shows the CAN-FD Parameter settings.

To calculate these set of parameters we need to use an external calculator, which could be found at https://www.kvaser.com/support/calculators/can-fd-bit-timing-calculator/

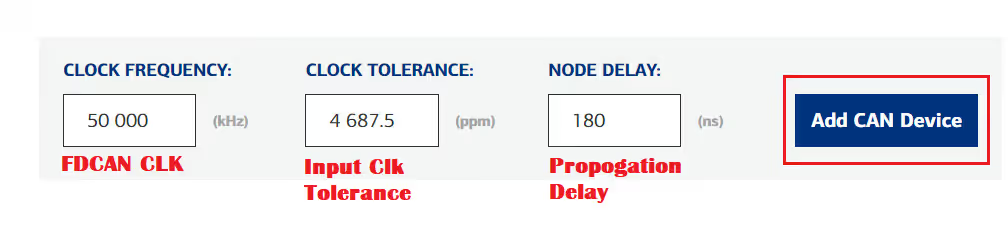

The first 3 parameters we need to input are the FDCAN CLK Frequency, The Input CLK Tolerance and the Transceiver node delay.

- The FDCAN clock Frequency is 50 MHz and we have already covered this in the clock configuration section.

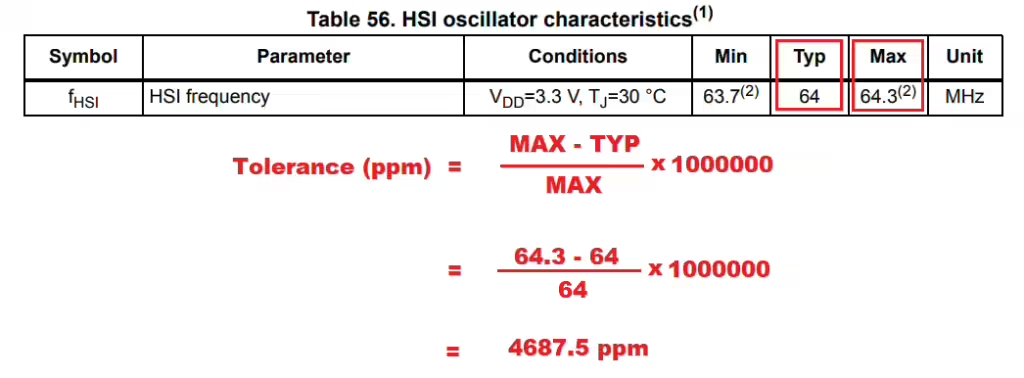

- Next comes the Clock Tolerance. I mentioned in the beginning that I am using the internal clock in this tutorial, and it was because it’s easier to find the clock tolerance for the input clock. The picture below is from the datasheet of STM32H745, showing the characteristics of HSI oscillator.

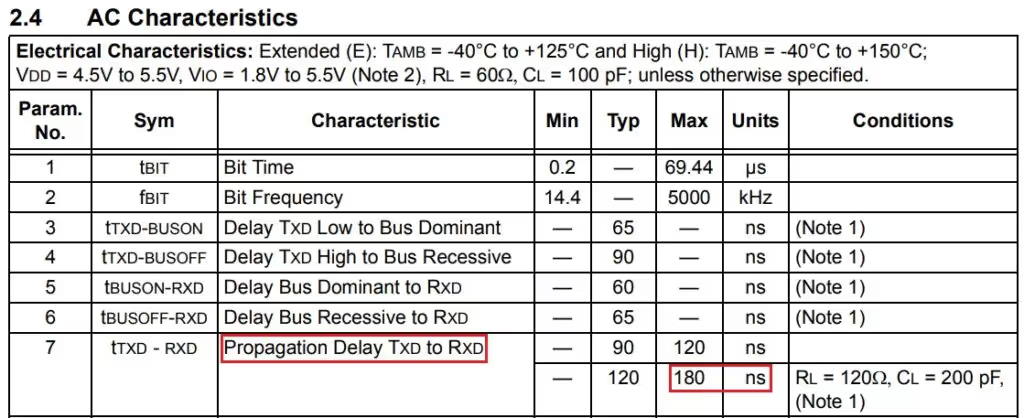

- Finally we have the node delay or Propagation Delay. This can be found in the AC characteristics of the Transceiver you are using. The image below shows the same for MCP2562FD, CAN-FD transceiver used in STM32H7 discovery.

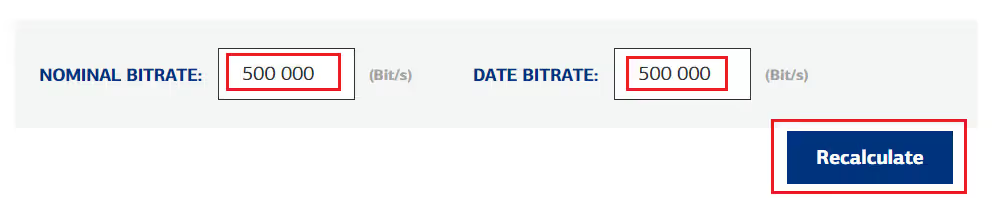

Next we have to input the bitrates that we want to set for the CAN-FD. As I already mentioned the FDCAN can transfer arbitration field and data filed at different bitrates. But I want to use the same bitrate for both of them, and that would be 500 Kbps. After you have entered the bitrates, click recalculate to calculate the values.

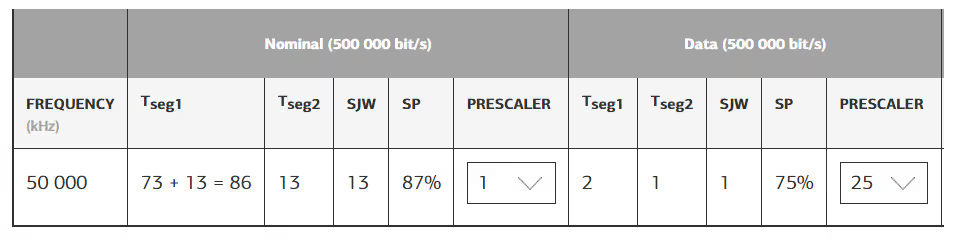

After we click the recalculate button, we will get the values of the parameters. This is shown in the picture below

We can input these values in the FDCAN parameters. You should use the same values in both FDCAN instances.

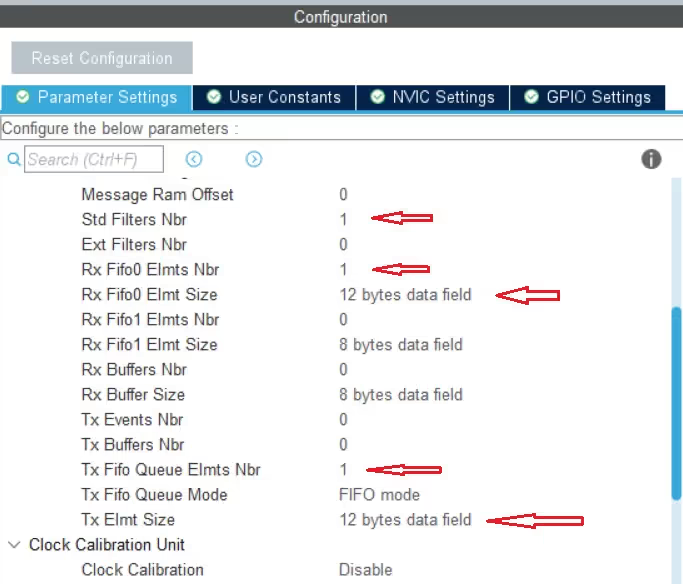

Now we will see the rest of the parameters. The arrows shows the parameters which has been modified.

- In the image above, the message Ram offset is set to 0. This is used in the multiple instances of the FDCAN and will be covered later in the tutorial.

Std Filters Nbris the number of standard (ID) filters we are using.- We can use up to 128 different filters configured to accept or reject messages from different IDs

- I am only using a single filter.

Ext Filters Nbris set to 0 because we are not using any Extended IDs in this tutorial- We will use the RX FIFO 0 to receive the message. Totally we can use up to 64 FIFO elements and each element can store up to 64 bytes of data.

- Here I am only using a single element to receive 12 bytes of data.

- I am not using any RX buffer or TX buffer, so all those parameters are set to 0.

- TX Fifo will be used to send the data to the CAN bus. So here I am using 1 element of the TX Fifo to send 12 bytes of data.

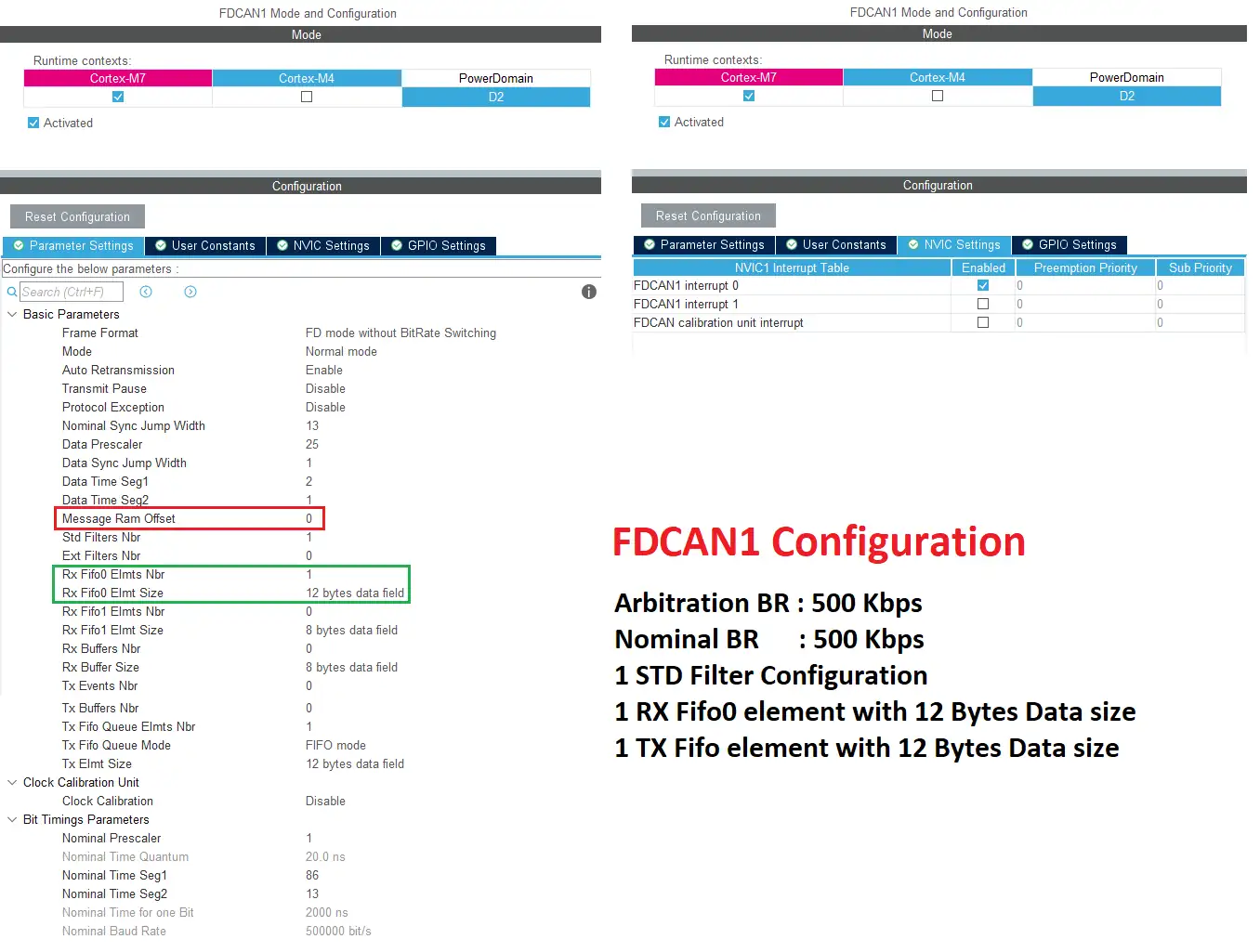

STM32 FDCAN Individual Configurations

So far we covered the common configuration needed for both the instances. Since we want the 2 instances to act as 2 separate devices, we need to configure them separately.

Below are the configurations for FDCAN1 and FDCAN2.

Other than the message RAM, one more change you can notice is that I am using the RX Fifo 0 for the FDCAN1, and RX Fifo 1 for the FDCAN2. This is simply because the 2 Fifos are available and I want to write completely separate codes for them.

Note that the message RAM offset for the FDCAN1 is 0, and that of the FDCAN2 is 11 words.

Why Message RAM Partitioning Matters in STM32 FDCAN

When using more than one STM32 FDCAN peripheral, correct message RAM partitioning is critical.

- STM32H7 provides 2560 words (~10 KB) of message RAM.

- You must allocate offsets for each FDCAN instance (e.g., FDCAN1 at offset 0, FDCAN2 at 11 words).

- Each filter, RX FIFO, and TX buffer consumes message RAM depending on data length.

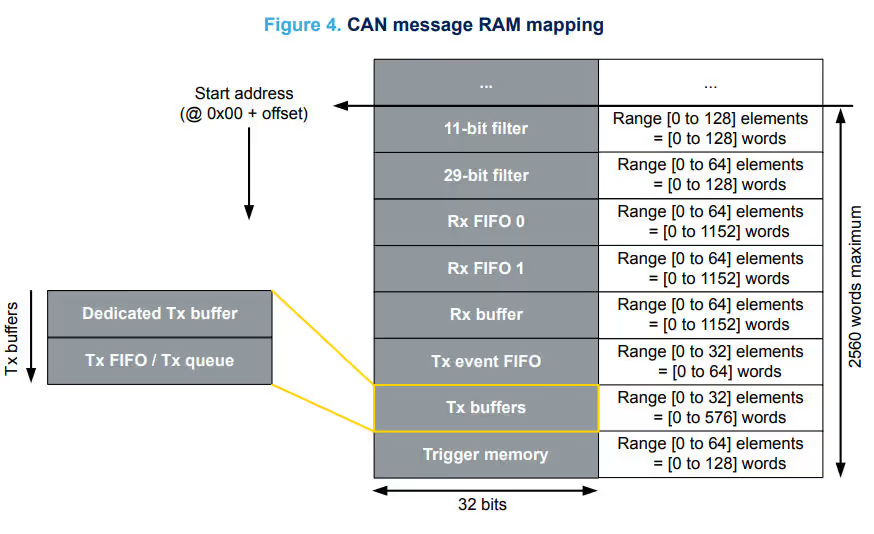

As per the application note AN5348, the FDCAN message RAM is 2560 words in size, which is equivalent to 10KB. This RAM is provided to store the different filters, RX buffers/FIFOs, the TX buffers etc.

Understanding the FDCAN Message RAM

If we are using more than 1 FDCAN instance, we have to carefully partition the RAM such that the total size of these sections do not exceed the ram size. Below is the image shown as per the application note.

Note that different sections have different number of elements available. These elements are basically the number of these sections we can use. For eg- There are 128 elements available in the standard filter (11 bit filter), so we can use 128 different standard filters.

Similarly there are 128 elements in the RX buffer, so we can use 128 different buffers to receive data, and each buffer is capable of storing upto 64 bytes of data.

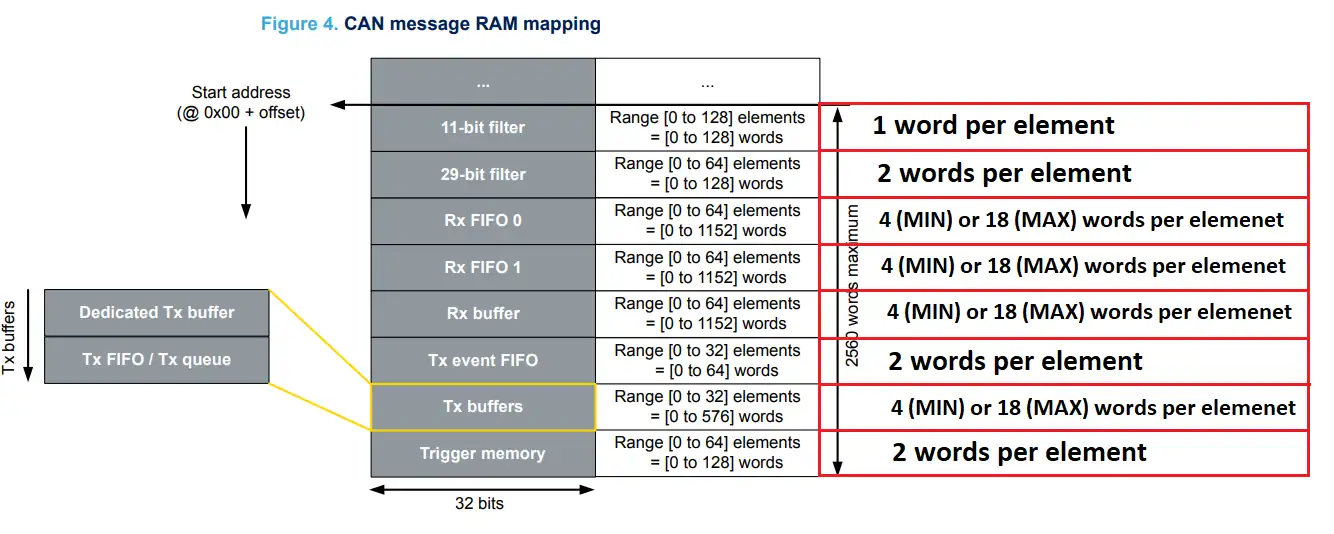

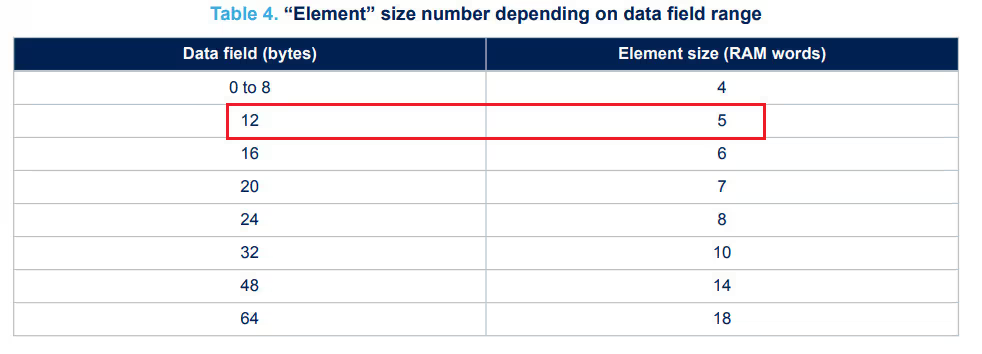

How much if the space will be occupied by each element of these sections is shown in the picture below.

For most of the sections, the calculation here is pretty simple, (number of words available / number of elements). Though this rule does not apply in case of TX and RX buffers/Fifos. For these sections, the occupied space also depends on the data size we are using.

In the FDCAN1 configuration I have set the message Ram offset to 0, so the allocation will start at the beginning of the RAM.

I am using 1 standard filter (1 word) + 1 RX Fifo element with 12 bytes of data (5 words) + 1 TX Fifo element with 12 bytes of data (5 words). This totally makes 11 words.

These 11 words will be needed by the FDCAN1 to work properly, so the offset for the FDCAN2 is set to 11. The rest of the RAM is available to the FDCAN2, though it will also use 11 words.

FDCAN Filter Configuration

Filters in FDCAN allow your STM32 to selectively receive messages from the network. By configuring filters, you can decide which message IDs your node should process and which ones to ignore. Proper filter setup improves bus efficiency and reduces unnecessary processing, especially on busy networks. In this section, we’ll look at how to configure FDCAN filters step by step, so your application only handles the messages it needs.

Filter configuration for FDCAN1

FDCAN_FilterTypeDef sFilterConfig;

sFilterConfig.IdType = FDCAN_STANDARD_ID;

sFilterConfig.FilterIndex = 0;

sFilterConfig.FilterType = FDCAN_FILTER_MASK;

sFilterConfig.FilterConfig = FDCAN_FILTER_TO_RXFIFO0;

sFilterConfig.FilterID1 = 0x22;

sFilterConfig.FilterID2 = 0x22;

sFilterConfig.RxBufferIndex = 0;

if (HAL_FDCAN_ConfigFilter(&hfdcan1, &sFilterConfig) != HAL_OK)

{

/* Filter configuration Error */

Error_Handler();

}- The IdType defines if we are using the Standard IDs or Extended IDs

- Filterindex is used in case of configuring the multiple filters. Since I am only using 1 filter, it is set to 0.

- FilterType is the type of filter we are using. Here I am using the MASK Filter.

- For this MASK Filter, the ID1 (0x22) will act as the ID and ID2 (0x22) will act as the mask bits.

- If you want to learn more about how this works, I would suggest that you watch https://youtu.be/JfWlIY0zAIc

- FilterConfig decides what should be done to the messages that pass through the filter. It is set to be sent to RX FIFO 0.

- RxBufferIndex is used if you use the RX Buffer instead of FIFO, so it is set 0 her.

So all the messages coming from the ID 0x22 will be passed through the filter and get stored in the RXFIFO0.

Filter configuration for FDCAN2

FDCAN_FilterTypeDef sFilterConfig;

sFilterConfig.IdType = FDCAN_STANDARD_ID;

sFilterConfig.FilterIndex = 0;

sFilterConfig.FilterType = FDCAN_FILTER_MASK;

sFilterConfig.FilterConfig = FDCAN_FILTER_TO_RXFIFO1;

sFilterConfig.FilterID1 = 0x11;

sFilterConfig.FilterID2 = 0x11;

sFilterConfig.RxBufferIndex = 0;

if (HAL_FDCAN_ConfigFilter(&hfdcan2, &sFilterConfig) != HAL_OK)

{

/* Filter configuration Error */

Error_Handler();

}Here everything is similar except the ID is set to 0x11, and we are using RXFIFO1.

So all the messages coming from the ID 0x11 will be passed through the filter and get stored in the RXFIFO1.

STM32 FDCAN Code Walkthrough

This section breaks down the essential code, explaining how each configuration step uses the FDCAN peripheral for normal operation.

Understanding HAL_FDCAN Functions in STM32

Many searches are for STM32 HAL functions directly. Here’s what they do:

HAL_FDCAN_AddMessageToTxFifoQ→ Queues data for transmission.HAL_FDCAN_ActivateNotification→ Enables interrupts for RX FIFO events.HAL_FDCAN_GetRxMessage→ Retrieves incoming messages from RX FIFO.HAL_FDCAN_ConfigFilter→ Defines filter IDs and routing.HAL_FDCAN_RxFifo0Callback / HAL_FDCAN_RxFifo1Callback→ Called when new messages arrive.

Let’s dive into the implementation. The following code initializes the FDCAN peripheral, configures the message RAM, and sets up filters to handle incoming messages.

Definitions

Below are the definitions we will use in this project.

// FDCAN1 Defines

FDCAN_TxHeaderTypeDef TxHeader1;

FDCAN_RxHeaderTypeDef RxHeader1;

uint8_t TxData1[12];

uint8_t RxData1[12];

// FDCAN2 Defines

FDCAN_TxHeaderTypeDef TxHeader2;

FDCAN_RxHeaderTypeDef RxHeader2;

uint8_t TxData2[12];

uint8_t RxData2[12];As shown above, the RX and TX headers are defined separately for both the FDCANs. Also the RxData and TxData arrays are 12 bytes in size.

Start the FDCAN Peripheral

We will write the start process for the FDCAN Peripheral inside the main function.

// STart FDCAN1

if(HAL_FDCAN_Start(&hfdcan1)!= HAL_OK)

{

Error_Handler();

}

// STart FDCAN2

if(HAL_FDCAN_Start(&hfdcan2)!= HAL_OK)

{

Error_Handler();

}

// Activate the notification for new data in FIFO0 for FDCAN1

if (HAL_FDCAN_ActivateNoatification(&hfdcan1, FDCAN_IT_RX_FIFO0_NEW_MESSAGE, 0) != HAL_OK)

{

/* Notification Error */

Error_Handler();

}

// Activate the notification for new data in FIFO1 for FDCAN2

if (HAL_FDCAN_ActivateNotification(&hfdcan2, FDCAN_IT_RX_FIFO1_NEW_MESSAGE, 0) != HAL_OK)

{

/* Notification Error */

Error_Handler();

}First of all Start both FDCAN1 and FDCAN2. Then Activate the notification for new message to arrive in their respective Fifos. This notification will trigger the interrupt, which will eventually call a callback function, and there we will handle the incoming data.

Prepare the TX Header

Next, prepare the TX header for both FDCAN, which will be transmitted along with the data on the can bus.. This header will remain the same and we can modify the data part later on the requirement. I am using maximum 12 bytes for data, hence it can also be declared in the beginning itself.

// Configure TX Header for FDCAN1

TxHeader1.Identifier = 0x11;

TxHeader1.IdType = FDCAN_STANDARD_ID;

TxHeader1.TxFrameType = FDCAN_DATA_FRAME;

TxHeader1.DataLength = FDCAN_DLC_BYTES_12;

TxHeader1.ErrorStateIndicator = FDCAN_ESI_ACTIVE;

TxHeader1.BitRateSwitch = FDCAN_BRS_OFF;

TxHeader1.FDFormat = FDCAN_FD_CAN;

TxHeader1.TxEventFifoControl = FDCAN_NO_TX_EVENTS;

TxHeader1.MessageMarker = 0;

// Configure TX Header for FDCAN2

TxHeader2.Identifier = 0x22;

TxHeader2.IdType = FDCAN_STANDARD_ID;

TxHeader2.TxFrameType = FDCAN_DATA_FRAME;

TxHeader2.DataLength = FDCAN_DLC_BYTES_12;

TxHeader2.ErrorStateIndicator = FDCAN_ESI_ACTIVE;

TxHeader2.BitRateSwitch = FDCAN_BRS_OFF;

TxHeader2.FDFormat = FDCAN_FD_CAN;

TxHeader2.TxEventFifoControl = FDCAN_NO_TX_EVENTS;

TxHeader2.MessageMarker = 0;The ID of the FDCAN1 is set to 0x11, and that of the FDCAN2 is set to 0x22. The rest of the parameters are same in both cases.

- The Identifier is the ID of the Transmitter, which is going to be 0x11 for the FDCAN1 and 0x22 for the FDCAN2.

- The IdType is set to Standard ID as we are not using Extended ID in this tutorial.

- TxFrameType implies whether we are sending a Data frame or Remote frame. It is set to Data Frame.

- DataLength is set to 12 bytes. This is the length of the actual Data we are going to send.

- ErrorStateIndicator is active and it will notify us if there is any error in transmission.

- BitrateSwitch is OFF, as I mentioned we will be using the same bitrate for both Arbitration and Data Fields

- FDFormat implies whether you want to use the standard CAN or FD CAN. It is set to FD_CAN

- We are not using the TxEvent or MessageMarker.

The infinite loop

Inside the while loop, we will make the the FDCAN1 to transmit the data every 1 second.

while (1)

{

sprintf ((char *)TxData1, "FDCAN1TX %d", indx++);

if (HAL_FDCAN_AddMessageToTxFifoQ(&hfdcan1, &TxHeader1, TxData1)!= HAL_OK)

{

Error_Handler();

}

HAL_Delay (1000);

}- The TxData contains a string (To indicate the data is coming from the FDCAN1) along with the incremented value of the indx variable.

- Then the function

HAL_FDCAN_AddMessageToTxFifoQwill add the message to the FIFO queue. - After the message is added to the FIFO Queue, it will be transferred to the CAN Bus

Once the message has been sent to the can bus, it will be received by all the devices that are attached to this bus (though we have only 1 more). And after the message passes through the filter of the FDCAN2, the new message callback will be called.

FDCAN2 Callback

Since the FDCAN1 transmits the data in the while loop, the FDCAN2 will receive this data. Once the data is passed through the FDCAN2 filters, an interrupt will trigger and the HAL_FDCAN_RxFifo1Callback will be called. We will handle the data received inside this callback.

// FDCAN2 Callback

void HAL_FDCAN_RxFifo1Callback(FDCAN_HandleTypeDef *hfdcan, uint32_t RxFifo1ITs)

{

if((RxFifo1ITs & FDCAN_IT_RX_FIFO1_NEW_MESSAGE) != RESET)

{

/* Retreive Rx messages from RX FIFO0 */

if (HAL_FDCAN_GetRxMessage(hfdcan, FDCAN_RX_FIFO1, &RxHeader2, RxData2) != HAL_OK)

{

/* Reception Error */

Error_Handler();

}

if (HAL_FDCAN_ActivateNotification(hfdcan, FDCAN_IT_RX_FIFO1_NEW_MESSAGE, 0) != HAL_OK)

{

/* Notification Error */

Error_Handler();

}

sprintf ((char *)TxData2, "FDCAN2TX %d", indx++);

if (HAL_FDCAN_AddMessageToTxFifoQ(&hfdcan2, &TxHeader2, TxData2)!= HAL_OK)

{

Error_Handler();

}

}

}The RxFifo1Callback will be triggered since we are using the Fifo1 for the FDCAN2.

- Here we will first copy the Header information from the RX FIFO1 into the RxHeader, and data into the RxData array.

- We will then activate the notification for the new message again.

- At last we will send some data on the CAN bus.

- This data contains the string (To indicate the data is coming from the FDCAN2) along with the incremented value of the indx variable.

Once the message has been sent to the can bus, it will pass through the filter of the FDCAN1 and the new message callback will be called.

FDCAN1 Callback

After receiving data from FDCAN1, the FDCAN2 processes this data and send something back to the CAN Bus. Once the data is passed through the FDCAN1 filters, an interrupt will trigger and the HAL_FDCAN_RxFifo0Callback will be called. We will handle the data received inside this callback.

// FDCAN1 Callback

void HAL_FDCAN_RxFifo0Callback(FDCAN_HandleTypeDef *hfdcan, uint32_t RxFifo0ITs)

{

if((RxFifo0ITs & FDCAN_IT_RX_FIFO0_NEW_MESSAGE) != RESET)

{

/* Retreive Rx messages from RX FIFO0 */

if (HAL_FDCAN_GetRxMessage(hfdcan, FDCAN_RX_FIFO0, &RxHeader1, RxData1) != HAL_OK)

{

/* Reception Error */

Error_Handler();

}

if (HAL_FDCAN_ActivateNotification(hfdcan, FDCAN_IT_RX_FIFO0_NEW_MESSAGE, 0) != HAL_OK)

{

/* Notification Error */

Error_Handler();

}

}

}The RxFifo0Callback will be triggered since we are using the Fifo0 for the FDCAN1.

- Here we will first copy the Header information from the RX FIFO0 into the RxHeader, and data into the RxData array.

- We will then activate the notification for the new message again.

Unlike the FDCAN2 callback, we are not transmitting any data here, since the data is being transmitted every second by the FDCAN1 in the while loop. This way the FDCAN1 will keep transmitting every 1 second, and FDCAN2 will always send a response to that.

Result of the STM32 FDCAN Communication

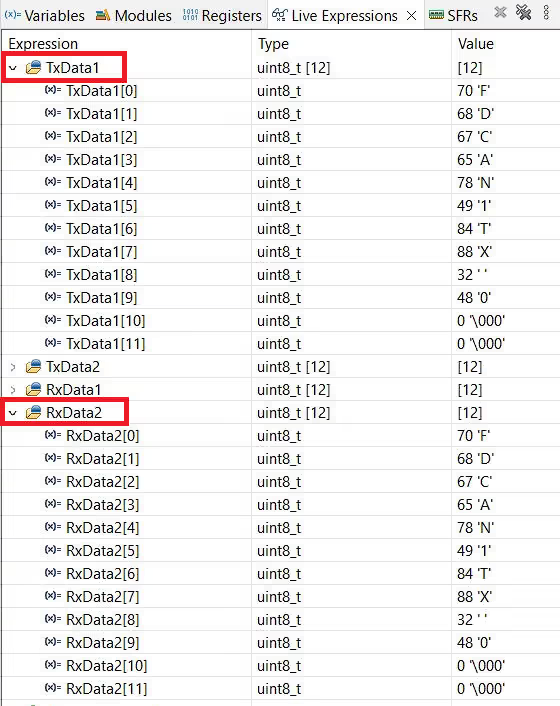

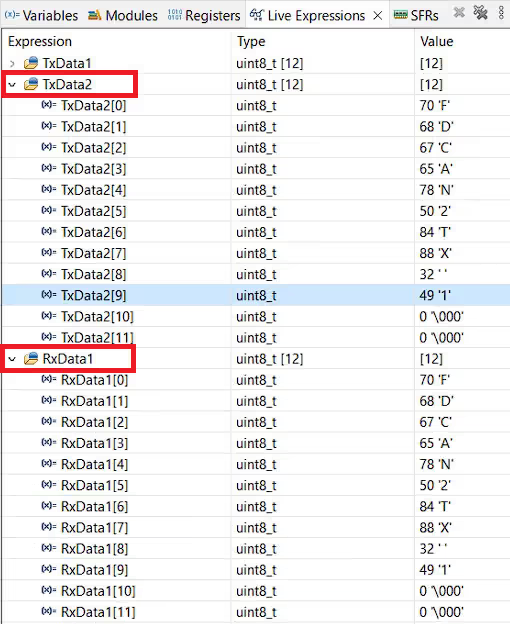

The images below shows the data transmitted by one instance and received by another instance of the FDCAN in STM32.

The first picture shows the data transmitted by FDCAN1 (TxData1) and the same data being successfully received by FDCAN2 (RxData2). The second picture shows a different data set transmitted by FDCAN2 (TxData2) and correctly received by FDCAN1 (RxData1).

This demonstrates that both FDCAN peripherals are communicating correctly, confirming that the transmission and reception setup is working in normal mode. It also verifies that the CANH and CANL connections are properly configured, and the data integrity is maintained across the network.

This test is important because it confirms reliable two-way communication between the nodes, which is essential in real-world applications like automotive systems, industrial automation, and robotics, where data must be accurately transmitted and received without errors.

Conclusion

In this tutorial, we saw how to set up and use FDCAN in normal mode on the STM32. We learned how to configure the hardware connections, set up the FDCAN peripherals, transmit and receive data between two nodes, and verify communication using simple test messages. We also explored the FDCAN frame structure, filters, and the differences between CAN 2.0 and CAN-FD frames. By following these steps, you now have a solid foundation to implement reliable CAN communication in your STM32 projects.

Other STM32 CAN Tutorials

STM32 FDCAN Project Download

Info

You can help with the development by DONATING Below.

To download the project, click the DOWNLOAD button.

STM32 FDCAN FAQs

Yes, but their bit timing parameters (Prescaler, Time Quanta, etc.) must be calculated separately to achieve the exact same nominal baud rate (e.g., 500 kHz) on both nodes for reliable communication.

The RX interrupt is typically triggered upon a successful filter match. The handler should quickly retrieve the message from the Rx FIFO and exit, allowing the core to process the data in the main loop or a queue, preventing missed messages.

They are functionally identical. The primary use for having two FIFOs is to prioritize certain messages by assigning higher-priority filters to one FIFO and lower-priority to the other, each with its own dedicated interrupt line.

Ensure you are using a terminated differential pair (120Ω resistor at each end of the bus) to prevent signal reflections. Also, verify the transceiver’s supply voltage and ensure the physical layer is properly isolated.

You must strategically partition the shared RAM in the master FDCAN instance’s initialization, allocating dedicated sections for each instance’s Rx/Tx elements and buffers to prevent memory conflicts and data corruption.

StdFiltersNbr=1, not 0 as in the screenshot of Setting for FDCAN2 Configuration.

Hi,

I have tried the exact same code on a H750 but it doesn’t seem to work, and I can’t figure out why. It uses the same FDCAN controller, so the timings should match. I get a TX signal that I can see on my oscilloscope, but FDCAN2 is not triggering the interrupt. I have tried changing just about every parameter, redid the whole project 3 times, but no success.

Any ideas?

Hi,

I have two FDCAN Devices, STM32H743 FDCAN1 and MCP2518FD-SPI CAN.

I am able to Transmit and Receive FDCAN messages between both FDCAN using Transceivers

[FDCAN1 <-Tx/Rx-> TCVR <-CAN_H/L-> TCVR <-Tx/Rx-> SPI-MCP2518FD]

But when I Connect FDCAN1’s Tx/Rx with SPI-MCP-FDCAN’s Rx/Tx,

[FDCAN1 <-Tx/Rx-> <-Rx/Tx-> SPI-MCP2518FD]

I am unable to Transmit and Receive Data between both FDCANs.

I am using Tx/Rx Buffers, Not Fifo for FDCAN1 and FIFO for SPI-MCP-CAN.

Also I am using FDCAN1 Polling, NOT interrupt method.

Both FDCAN are working fine with Internal Loopback Testing.

I have problem in Tx/Rx in Normal FDCAN Mode only.

How can it work without the transceivers ? What would be the need for the transceivers then ?

In loopback mode, the Tx pin The Tx pin is internally connected to the Rx pin, so it’s like you sort the pins together. The message sent on the Tx pin just reverts back to Rx pin.

Loopback mode is just to test if the configuration is correct. It has nothing else to do with the normal mode.

Thanks for your videos. I tried it with a NUCLEO-H7A3ZI-Q and SN65HVD233DR, but the Txbuffer is full after two cycle of task and I got error code 512 (HAL_FDCAN_ERROR_FIFO_FULL).

Please, help me.