Master – slave communication using LinBus

This is the 9th tutorial in the series on the UART peripheral of STM32 Microcontrollers. In this series we will cover different ways of transmitting and receiving data over the UART protocol. We will also see different UART modes available in the STM32 microcontrollers and how to use them.

This tutorial is the PART3 in the small series covering the Lin protocol. In today’s tutorial we will program the master to send some commands to the slave device. The slave device will perform the actions based on the received command. We will also program the slave device to send data on the Linbus whenever requested by the master.

In the previous tutorial we have covered how to connect the Lin transceiver to the MCUs. We also sent the data over the Linbus, which was then received by the slave.

Connection

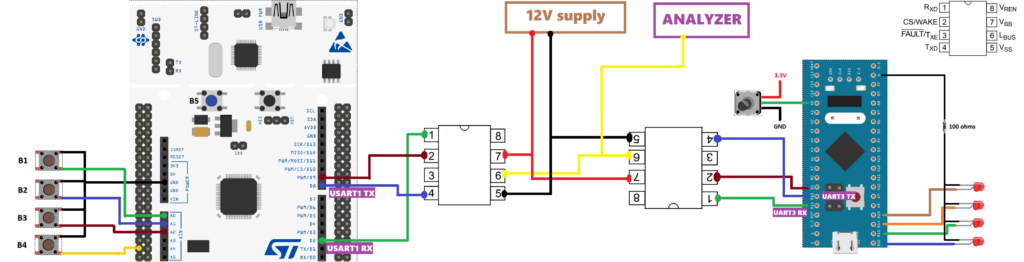

This tutorial is a continuation of the previous one, so we will just add few more things to the connection shown previously. Below is the image showing the connection diagram for this tutorial.

As shown above, there are a total of 5 buttons (4 External + 1 on board) connected to the master MCU. The 4 external buttons are connected to the pins PA0, PA1, PA4 and PC2. The on board user button is connected to the pin PC13.

The 4 external buttons will control the LEDs connected to the slave MCU. The button B5 will be used to request the ADC data from the slave. On pressing each button, a specific command will be sent by the master. This command will be read and processed by the slave MCU.

The 4 LEDs on the slave MCU are connected with the pins B12, B13, B14 and B15. There is a potentiometer connected to the pin PA0, whose value will be accessed using the ADC. The ADC value will be then sent by the slave to the master.

The Master

CubeMX Configuration

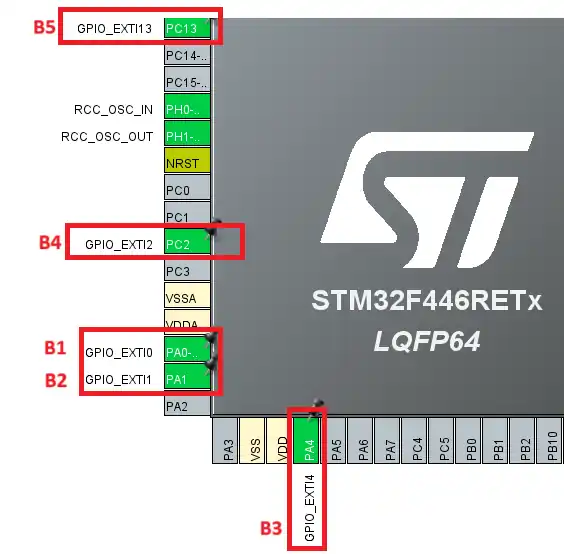

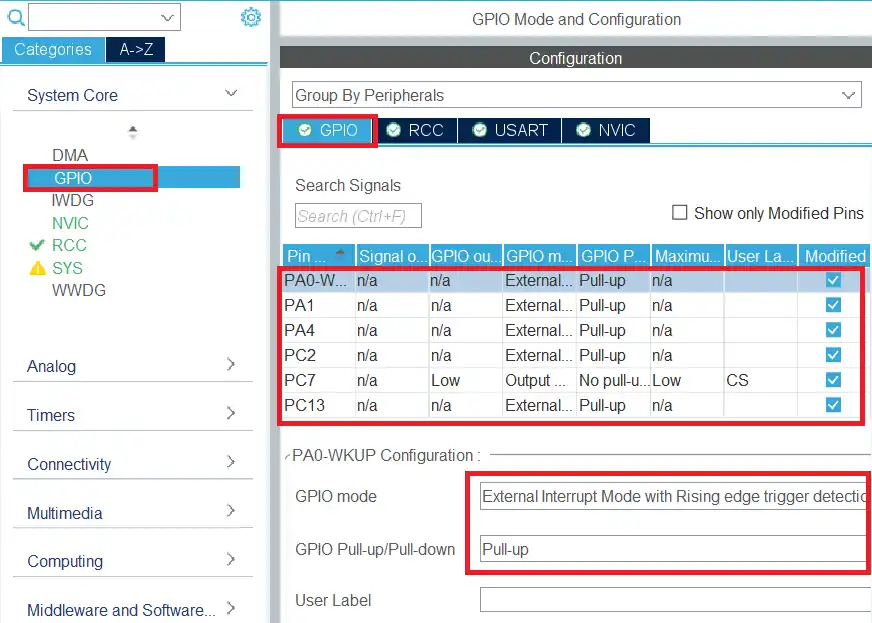

The basic configuration will remain the same as we covered in the previous tutorial. Here we will just add the buttons to this configuration. This is shown below.

As shown in the image above, I have set 5 different pins as the EXTI pins. The pins are chosen such that there is no conflict between the external interrupts.

All the buttons are connected between the MCU pin and the ground. Therefore when the button is pressed, respective pin is pulled low to the ground.

To ensure that the pin is pulled low to the ground only after the button is pressed, we need to enable the pull up for all the pins.

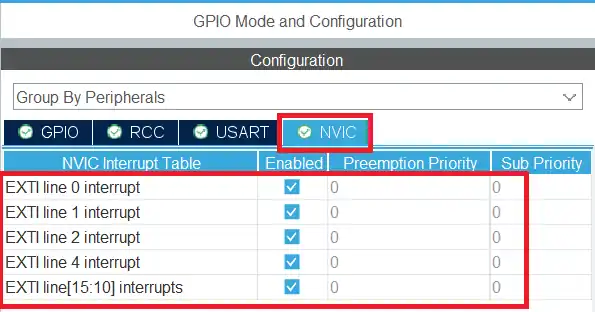

Finally we need to enable the interrupts for all the EXTI pins. This can be done in the NVIC Tab.

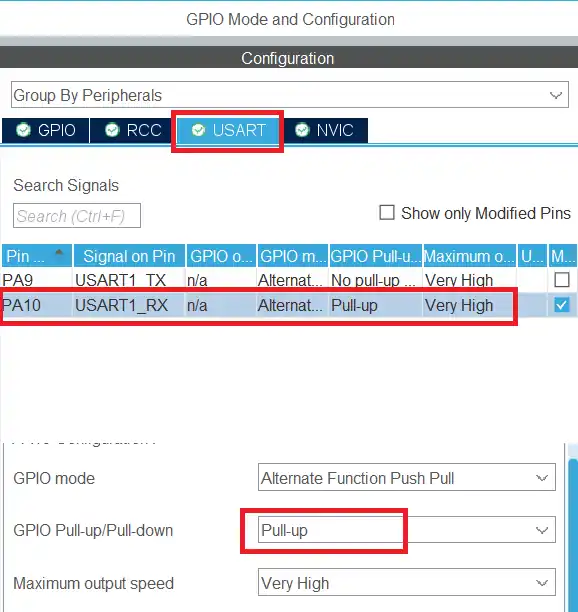

Since the master is also going to receive the data, we need to make sure that the UART RX pin is pulled high for the master. This can be done in the USART tab as shown below.

The Code

When either of the button is pressed, an interrupt will trigger and the External Interrupt callback is called.

int B1=0, B2=0, B3=0, B4=0, B5=0, transmit=0;

void HAL_GPIO_EXTI_Callback(uint16_t GPIO_Pin)

{

if (GPIO_Pin == GPIO_PIN_0)

{

B1 = transmit = 1;

B2 = B3 = B4 = B5 = 0;

}

else if (GPIO_Pin == GPIO_PIN_1)

{

B2 = transmit = 1;

B1 = B3 = B4 = B5 = 0;

}

else if (GPIO_Pin == GPIO_PIN_4)

{

B3 = transmit = 1;

B1 = B2 = B4 = B5 = 0;

}

else if (GPIO_Pin == GPIO_PIN_2)

{

B4 = transmit = 1;

B1 = B2 = B3 = B5 = 0;

}

else if (GPIO_Pin == GPIO_PIN_13)

{

B5 = transmit = 1;

B1 = B2 = B3 = B4 = 0;

}

}Inside the callback we will check which pin called this callback. Then set the respective variable and reset the other variables. We will also set the transmit variable with each button pressed, so that the master can transmit the data on the Linbus.

We will take care of the data transmission part inside the while loop.

while (1)

{

if (transmit == 1)

{

HAL_Delay(300);

TxData[0] = 0x55; // sync field

TxData[1] = pid_Calc(0x34);

TxData[2] = (B1<<0) | (B2<<1) | (B3<<2) | (B4<<3) | (B5<<4);

TxData[3] = checksum_Calc(TxData[1], TxData+2, 1); //lin 2.1 includes PID, for line v1 use PID =0Inside the while loop, we will only transmit the data if the transmit variable is set. The delay (300ms) is used to prevent the button debouncing.

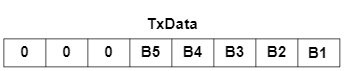

The TxData array will contain the Linbus frame to be transmitted. It contains the header field, the Sync field, The PID, the Data byte and the checksum byte.

The Data byte is the combination of the value of all the variables defined for the buttons. We basically use the button values as a single bit and combine them in the data byte.

Now the TxData buffer is prepared so we will send it via the Linbus.

HAL_GPIO_WritePin(CS_GPIO_Port, CS_Pin, GPIO_PIN_SET);

HAL_Delay(100);

HAL_LIN_SendBreak(&huart1);

HAL_UART_Transmit(&huart1, TxData, 4, 1000);

HAL_GPIO_WritePin(CS_GPIO_Port, CS_Pin, GPIO_PIN_RESET);

transmit = 0;To send the lin frame, the master will first set the CS pin. This will enable the transmitter in the Lin Transceiver. After that, the master will send the break field, followed by the TxData array.

Once the entire frame is transmitted, the master will reset the CS pin to disable the transmitter. This will prevent any data conjunction on the Linbus when the slave is transmitting the data.

When the button 5 is pressed, the slave will transmit the data containing ADC value. The master shall be prepared to receive this data.

if (HAL_UART_Receive(&huart1, RxData, 6, 500) == HAL_OK)

{

uint8_t checksum = checksum_Calc(RxData[2], RxData+3, 2);

if (checksum == RxData[5])

{

ADC_DATA = RxData[3] | (RxData[4]<<8);

}

}

}

}The HAL_UART_Receive is used to receive the 6 bytes of data in the blocking mode. I have used a timeout of 500ms. If the 6 bytes data is not received within this time, the function will timeout and the if condition will fail, otherwise we will have a valid data from the slave.

If all the 6 bytes are received, we will first calculate the checksum to verify if the data received is correct. The 12 bit ADC data is sent by the slave in 2 separate bytes. We will combine these bytes to make a single 12 bit data.

The Slave

CubeMX Configuration

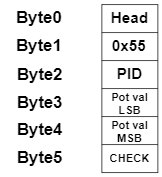

The basic configuration will remain the same as we covered in the previous tutorial. Here we will just add the LEDs to this configuration. This is shown below.

The 4 LEDs are connected to the pins PB12, PB13, PB14 and PB15. These LEDs will be controlled by the buttons on the master. We also have the potentiometer connected to the slave, which will be read using the ADC pin PA0.

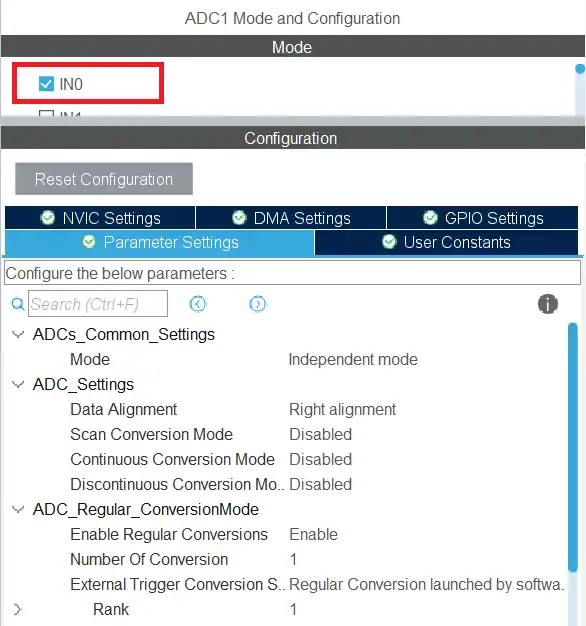

I have enabled the channel 0 of the ADC 1. The ADC is configured with the default setup.

The Code

Most of the code remains the same as we covered in the previous tutorial. The slave receives the data via the UART in the interrupt mode, checks the data validity, and if the data is valid, it extracts the actual data bytes from the received frame.

Here we will just cover the main function.

while (1)

{

if (isDataValid == 1)

{

for (int i=0; i<numDataBytes; i++)

{

Data[i] = RxData[i+3];

}Here we will check if the isDataValid variable is set to 1. If it is, then we will copy the received data from the RX buffer to the Data buffer. The master sent only 1 Data byte and it contains the information about which button is pressed.

Based on the this information, we will set the respective LED.

HAL_GPIO_WritePin(GPIOB, GPIO_PIN_12, (Data[0]&0x01));

HAL_GPIO_WritePin(GPIOB, GPIO_PIN_13, ((Data[0]>>1)&0x01));

HAL_GPIO_WritePin(GPIOB, GPIO_PIN_14, ((Data[0]>>2)&0x01));

HAL_GPIO_WritePin(GPIOB, GPIO_PIN_15, ((Data[0]>>3)&0x01));The 4 buttons are used to control 4 LEDs on the slave. The fifth button however requests the ADC data from the slave.

if (((Data[0]>>4)&0x01) == 1)

{

HAL_ADC_Start(&hadc1);

HAL_ADC_PollForConversion(&hadc1, 100);

uint16_t adcVal = HAL_ADC_GetValue(&hadc1);

HAL_ADC_Stop(&hadc1);We first check is the fifth button is pressed. If it is, the slave will start reading the ADC value. Here I am using the simple polling method to read the ADC value and it is stored in the adcVal variable. The STM32F103C8 has the 12 bit ADC resolution by default, hence we need to define a 16 bit variable to store the value.

Now that we have the ADC value, we will send it via the Linbus. To do that, we first need to prepare the Lin frame to be transmitted.

uint8_t TxData[10];

TxData[0] = 0x55; // sync field

TxData[1] = pid_Calc(0x35);

TxData[2] = adcVal&0xFF;

TxData[3] = (adcVal>>8)&0xFF;

TxData[4] = checksum_Calc(TxData[1], TxData+2, 2); //lin 2.1 includes PID, for line v1 use PID =0The TxData array will contain the lin frame. We will store the sync filed, followed by the PID, the actual Data bytes and finally the checksum byte.

Here I am using a separate ID for the slave, 0x35. Since the ADC Data is 12 bit in size, we need to send it in 2 separate bytes, with the LSB being sent first.

We have the lin frame, so the next part is to transmit this frame via the UART.

HAL_GPIO_WritePin(CS_GPIO_Port, CS_Pin, GPIO_PIN_SET);

HAL_Delay(100);

HAL_LIN_SendBreak(&huart3);

HAL_UART_Transmit(&huart3, TxData, 5, 1000);

HAL_GPIO_WritePin(CS_GPIO_Port, CS_Pin, GPIO_PIN_RESET);

}

isDataValid = 0;

}

}To send the lin frame, the slave will first set the CS pin. This will enable the transmitter in the Lin Transceiver. After that, the slave will send the break field, followed by the TxData array.

Once the entire frame is transmitted, the slave will reset the CS pin to disable the transmitter. This will prevent any data conjunction on the Linbus when the master is transmitting the data.

Once all the processing is done, reset the isDataValid variable to 0. This will prevent this loop from running again until the next data is sent by the master.

Result

You can check the video below to see the entire working.

Did you get any example about the most real slave?

If you are preparing example on LIN communication, please do it like it is done in real cases. The master shall request the data from the Slave by sending header only. Then the slave shall response with the data only. Tbh your example is useless without this mechanism. Also receving fixed size data with polling mode is very bad way to do it.

Did you get any example about the most real slave?